Simplified wiring and the elimination of hydraulic parts reduces the need for maintenance and risks related to component wear. The obvious advantage is that the machine is more reliable and safer.

It takes just a moment to start production: import the file directly from 3d CAD or input the wire geometric data. The VGP3D software automatically creates the machine program and starts production right away.

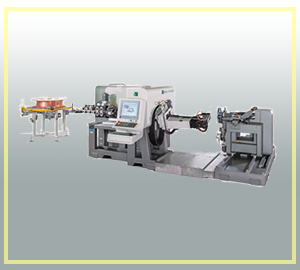

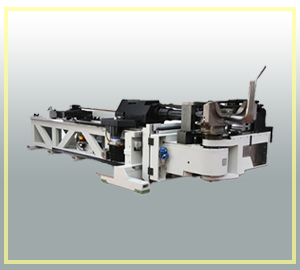

Types of CNC Wire Bending Machines

Tube Bending Machines in Hyderabad

Tubes can be bent by implementing different technologies depending on the application.

Simply combine the functions you need to easily identify the tube bending machine (in Hyderabad) most suited to your needs:

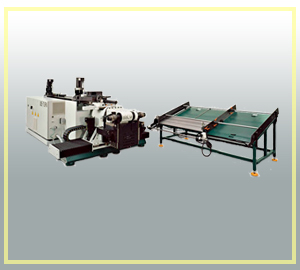

• with right-handed and left-handed in-process bending capabilities

• with configurable right-handed and left-handed bending capabilities

• with fixed and/or variable radius

• with manual loading or automatic loading from coil

• combined with other jobs

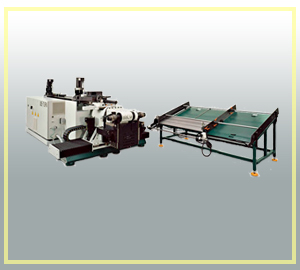

All machine movements are via electric servos. Part bend positions, tooling information, and power parameters are all saved together in the part program. When a job is repeated you simply mount the tools and recall the program. No further mechanical adjustments are needed. This guarantees quick setup and changeover and provides lot to lot repeatability.

All electric operation offers simplified wiring and the elimination of hydraulic components. This reduces the need for routine maintenance and provides more consistent bending. The obvious advantage of our CNC tube bending machines in Hyderabad is that the machine is easier to maintain, safer to use and more reliable.

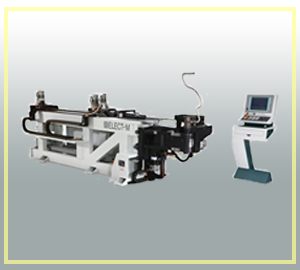

Normally a bender operator needs expertise in order to compensate for variations. At Tech Mach we have incorporated our many years of bending know-how in the CNC of our tube benders. Now you can get perfect results regardless of the operator’s skill.

Simply enter the standard bending data and the machine will automatically generate the part program after searching for prior bending experience in its database to make sure that it is right from the first part. And this works for either fixed or variable radius bends. Always.

This capability eliminates the need for those manual adjustments which were once indispensable to obtain good finished parts.