Best price to quality ratio - delivered

Rotators

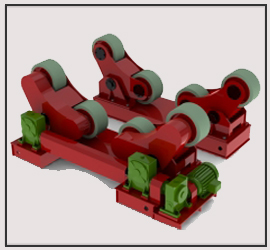

HGJ Rotators

Perfect welding auxiliary equipment-Roller Choose suitable rollers to meet kinds of welding requirements.

Applications

Dyeing Mechanized Welding

Longitudinal and Circumferential

Storage Tank

The rollers are widely used for automotive circumferential seam welding applications. They are necessary devices for automatic welding of pressure vessels and are advantageous in their reliable high quality, advanced performance, simplicity of operation.

Features

Rollers are divided into adjustable rollers and self-aligning rollers;

The extended width of wheels reduces the possibility of plastic deformation on work-piece surface, especially for thin-walled barrel;

The drive motor can insure the system's smooth running at a low speed;

The multiple-stage gear reducer features a big torque output;

The peripheral speed of the wheels is stable and even.

Specification

|

HGJ-C Adjustable Roller |

Maximum Load (kg) |

Structure Type |

Work piece Diameter (mm) |

Roller Speed (mm/min) |

Speed Adjustment Type |

|

|

HGJ-2C |

Radial adjusting |

2000 |

Master and slavery rollers |

Ф300-Ф2500 |

100-1000 |

Variable frequency |

|

Bolt adjusting |

Ф200-Ф2500 |

|||||

|

HGJ-5C |

Screw mandrel adjusting |

5000 |

Master and slavery rollers |

Ф250-Ф2300 |

100-1000 |

Frequency control |

|

HGJ-10C |

Screw mandrel adjusting |

10000 |

Master and slavery rollers |

Ф300-Ф2800 |

100-1000 |

Frequency control |

|

HGJ-20C |

Screw mandrel adjusting |

20000 |

Master and slavery rollers |

Ф500-Ф3500 |

100-1000 |

Frequency control |

|

HGJ-40C |

Screw mandrel adjusting |

40000 |

Master and slavery rollers |

Ф600-Ф4200 |

100-1000 |

Frequency control |

|

HGJ-S Self-aligning Rollers |

Maximum Load (kg) |

Structure Type |

Work Piece Diameter (mm) |

Roller Speed (mm/min) |

Speed Adjustment Type |

|

|

HGJ-10S |

Wheel dip angle 90° |

10000 |

Master and slavery rollers |

Ф320-Ф2800 |

100-1000 |

Frequency control |

|

Wheel dip angle 120° |

Ф320-Ф3600 |

|||||

|

HGJ-20S |

90°Wheel dip angle 90° |

20000 |

Master and slavery rollers |

Ф500-Ф3500 |

100-1000 |

Frequency control |

|

120°Wheel dip angle 120° |

Ф500-Ф4300 |

|||||

|

HGJ-40S |

90°Wheel dip angle 90° |

40000 |

Master and slavery rollers |

Ф600-Ф4200 |

100-1000 |

Frequency control |

|

120°Wheel dip angle 120° |

Ф600-Ф5000 |

|||||

|

HGJ-60S |

Wheel dip angle 90° |

60000 |

Master and slavery rollers |

Ф750-Ф4800 |

100-1000 |

Frequency control |

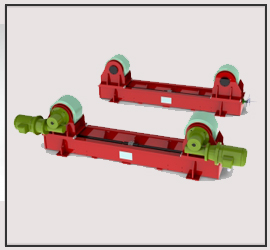

Screw Adjust Rotator

This rotator is main used for welding, fit up and polishing of the round cylinder in industrial like wind power, pressure vessel, petrochemical, piping, steel profile, boiler, ship yard, cladding repair etc.

Applications

Stainless Steel Pipe

Longitudinal and Circumferential

Cryogenic LNG Cylinder

This rotator is main used for welding, fit up and polishing of the round cylinder in industrial like wind power, pressure vessel, petrochemical, piping, steel profile, boiler, ship yard, cladding repair etc. Adopts worm gear double motor for smooth rotating, the distance between the rollers is adjustable by screw to fit for different work piece diameter, Speed can be displayed and AC variable controlled by remote pendant.

Specification

|

Specification |

FGJ-5C |

FGJ-10C |

FGJ-20C |

FGJ-40C |

|||

|

Payload(T) |

5 |

10 |

20 |

40 |

|||

|

Work diameter |

Min.(mm) |

250 |

300 |

500 |

600 |

||

|

|

Max.(mm) |

2300 |

2800 |

3500 |

4200 |

||

|

Motor power(kw) |

2x0.37 |

2x0.55 |

2x1.1 |

2x1.5 |

|||

|

Speed(mm/min) |

100-1000 |

||||||

|

Speed adjustment |

AC variable speed |

||||||

|

Polyurethane roller |

Diameter(mm) |

250 |

300 |

350 |

400 |

||

|

|

Width(mm) |

150 |

170 |

200 |

250 |

||

|

Dimension |

Power

|

Length(mm) |

2000 |

2260 |

2900 |

3300 |

|

|

|

|

Width(mm) |

490 |

600 |

610 |

740 |

|

|

|

Driven |

Length(mm) |

1800 |

2000 |

2700 |

3000 |

|

|

|

|

Width(mm) |

380 |

440 |

490 |

600 |

|

|

|

Height(mm) |

490 |

550 |

660 |

740 |

||

|

Code |

330101-0000-0000-00 |

330102-0000-0000-00 |

330103-0000-0000-00 |

330104-0000-0000-00 |

|||

Adaptive Rotator

This rotator is main used for welding, fit-up and polishing of the round cylinder in industrial like wind power, pressure vessel, petrochemical, piping, steel profile, boiler, ship yard, cladding repair etc. Adopts worm gear motor driving the four rollers, achieves smooth full-gear transmission.

Applications

Food Processing Mechanized Welding

Longitudinal and Circumferential

Storage Tank

This rotator is main used for welding, fit-up and polishing of the round cylinder in industrial like wind power, pressure vessel, petrochemical, piping, steel profile, boiler, ship yard, cladding repair etc. Adopts worm gear motor driving the four rollers, achieves smooth full-gear transmission. The four rollers will swing to different angle to fit for different work piece diameter. The rollers are polyurethane cover and can also be customized to steel for special usage. Speed can be displayed and AC variable controlled by remote pendant.

Specification

| Specification |

FGJ-10S |

FGJ-20S |

FGJ40-S |

FGJ60-S |

FGJ80-S |

||

|

Payload(T) |

10 |

20 |

40 |

60 |

80 |

||

|

Work piece |

Min.(mm) |

320 |

500 |

600 |

750 |

850 |

|

|

Max.(mm) |

3600 |

4300 |

5200 |

5500 |

6000 |

||

|

Motor power(kw) |

1.1 |

1.5 |

3 |

4 |

4 |

||

|

Speed(mm/min) |

100-1000 |

||||||

|

Speed adjustment |

AC variable speed |

||||||

|

Polyurethane roller |

Diameter(mm) |

330 |

330 |

450 |

450 |

490 |

|

|

Width(mm) |

100 |

100 |

200 |

200 |

240 |

||

|

Dimension |

Power |

Length(mm) |

1800 |

2200 |

2500 |

2800 |

3040 |

|

Width(mm) |

830 |

960 |

1150 |

1240 |

1540 |

||

|

Driven |

Length(mm) |

1600 |

1900 |

2200 |

2400 |

2670 |

|

|

Width(mm) |

420 |

490 |

530 |

590 |

620 |

||

|

Height(mm) |

730 |

850 |

970 |

1130 |

1240 |

||

|

Code |

330201-0000-0000-00 |

330202-0000-0000-00 |

330203-0000-0000-00 |

330204-0000-0000-00 |

330205-0000-0000-00 |

||

#634, 3rd cross, HMT layout,

Ganganagar, R T Nagar, Bangalore-560032.

Karnataka State, INDIA.

+91 98450 68437

skr@techmach.in

sales@techmach.in