One of the goals of automation and Industry 4.0 is to manufacture small batches, customizing every single part but with costs comparable to large series.

Gasparini studies the most suitable plant to your needs, allowing you to make your manufacture more flexible while reducing variability and processing errors.

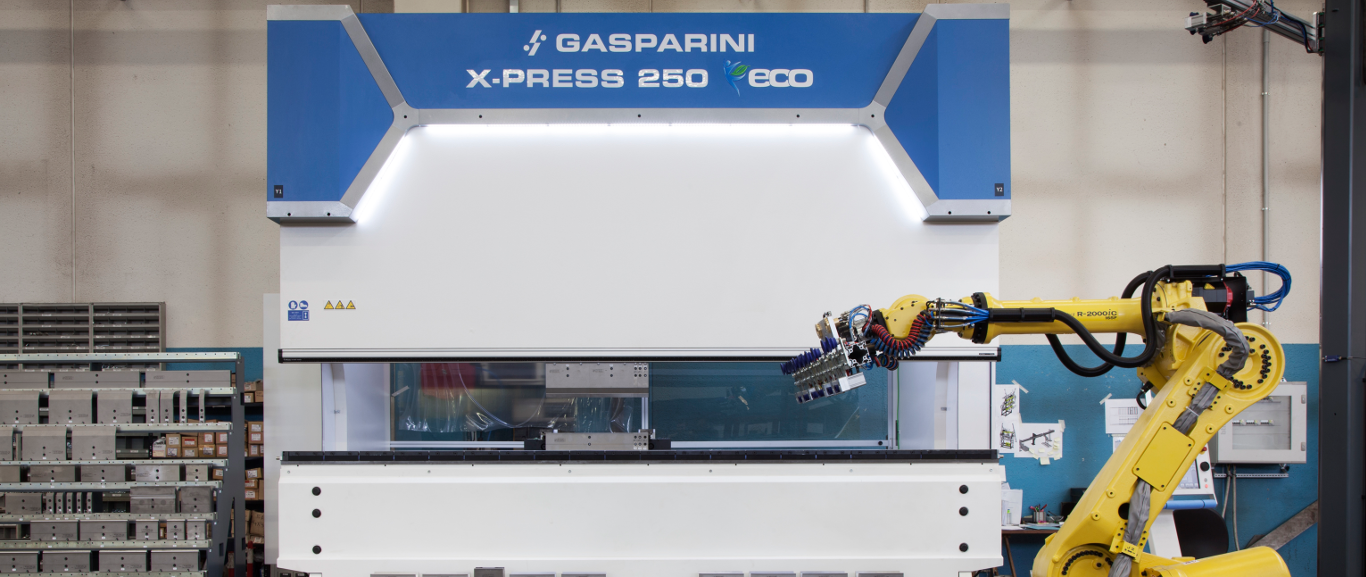

We are able to design and produce robot bending cells, manipulators and automations. We can supply automated bending lines that can be integrated to the rest of your productive structure, helping turning it into a true Smart Factory. We are also able to design and produce complete shearing lines with picking, stacking, manipulators, and many other types of plants.

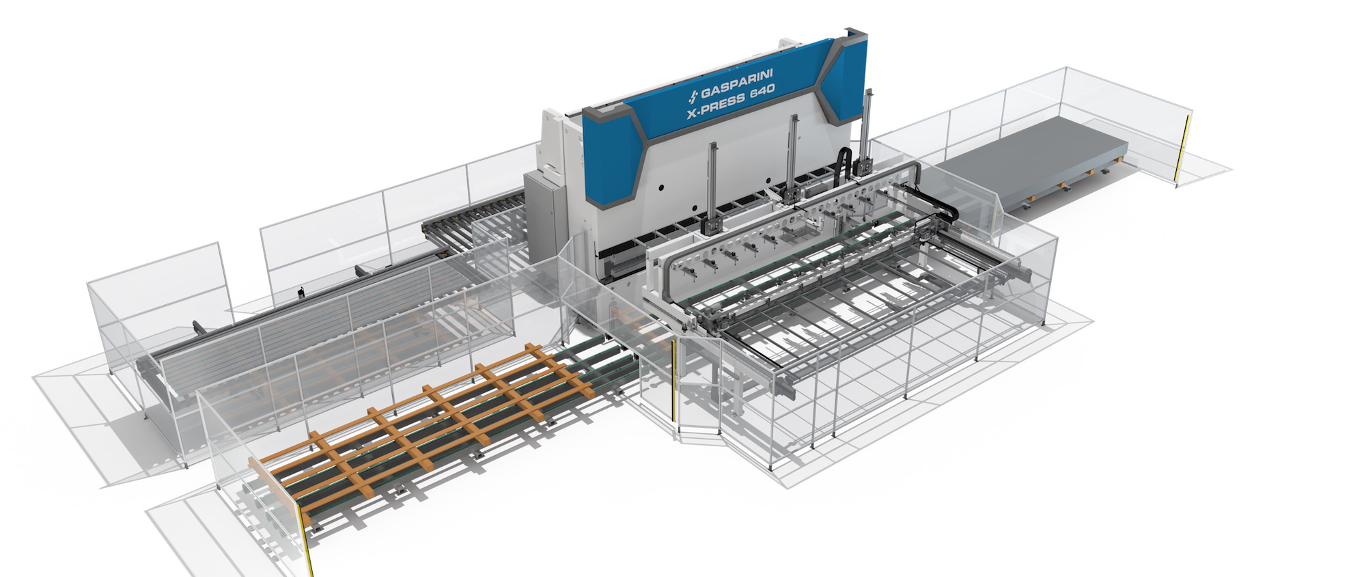

Automated 4.0 bending lines are a flexible alternative to roll forming lines, and are perfect for those who make corrugated sheets or other panels, but needs to frequently change dimensions and shapes. Thanks to automated manipulators you can handle parts of any size.

With an automated bending or shearing line you will turn your company into a true 4.0 Smart Factory, flexible and competitive.

Gasparini bending lines are totally compliant to Industry 4.0 guidelines, thanks to many features that can be developed according to the specific application. Our Research & Development office can design and manufacture machines equipped with:

An automated yet flexible and reconfigurable plant allows to reduce waste and accurately determine production times and costs. By leveraging vital information on your workflows you will be able to monitor the material characteristics, check production steps, and reduce the risk of faults. By connecting bending to other machine tools and corporate LAN you can track workflows and control bottlenecks.

Gasparini has a long experience in the production of shearing lines, from the most simple ones to large robotic plants. Our shears are versatile and powerful, and can be inserted into fast and high-volume production cycles, with the highest cutting quality and reliability.