Best price to quality ratio - delivered

Bending

Bending

We specialize in the design and manufacturing of equipment for any tube section and special profiles. Equipment for fixed or variable radius bending, "L" dies, or expansion dies.

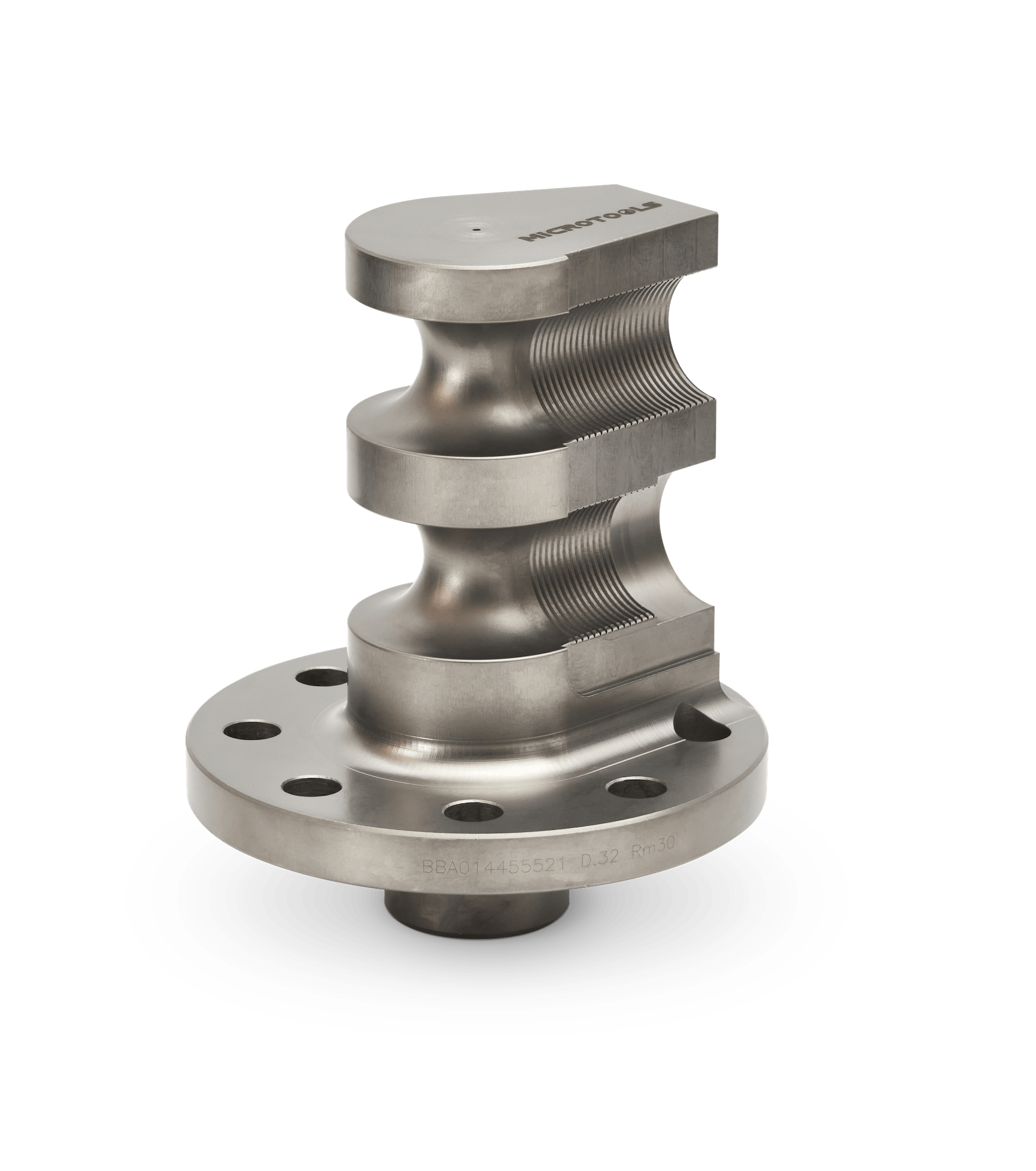

Mandrels

Mandrels are essential for achieving precise bends on thin-walled tubes with tight centerline radius, reducing deformations and wrinkles.

Inserted inside the tube during processing, they ensure a perfect finish and adherence to the required tolerances.

Customized Production

We design and manufacture mandrels in various materials such as bronze, steel and plastic. For non-ferrous tubes, we supply mandrels in steel with coating to avoid pasting with the tubes.

Mandrels Type:

- Monodirectional mandrels

- Omnidirectional mandrels (standard, close pitch, super close pitch)

- Plug mandrels

- Mandrels for square and rectangular tubes

Collets

Collets are used in almost all bending equipment and their purpose is to stop the tube’s bending during its various position and rotation sequences.

In some cases, the collets, equipped with a specific guide, can perform an active bending action (booster system), which is used in applications where the difficulty coefficient is higher.

Different Types of Finish

Collets are configured as tools with various types of finish:

- EDM high roughness

- Longitudinal finish (to ensure greater grip during the rotation of long and heavy tubes)

- Pyramidal finish (this type of finish provides the maximum possible grip)

- Smooth

Depending on the requirements, it is possible to adopt a different degree of finish, accordingly with high levels of finishing.

Unbeatable Efficiency

Our collets are designed and manufactured to offer you the achievement of truly high quality levels, both in purely functional terms and from an aesthetic point of view, contributing to the realization of machining operations marked by unbeatable efficiency.

Customized Solutions

Depending on the customer's needs, we design and manufacture collets capable of meeting the required specifications, offering the right support at the right time with our comprehensive consulting service.

Booster System

In specific cases, with an high level of difficulty, the collet can also perform an active bending action. In these instances, the collet is accompanied by the Booster guide system, capable of performing a control function.

Dies

Custom Design and Manufacturing

Bending dies are essential components that ensure precision and repeatability in the tube bending process.Choosing the right die is crucial to achieve the desired bend radius keeping the required tolerances.

Types of Bending Dies

We manufacture various configurations of tube bending dies, including:

- Stackable Dies: Ideal for working with tubes of different diameters using a single structure.

- Solid Dies: Perfect for tubes with different centerline radius or shaped clamps.

- Dies with interchangeable inserts: Available with straight or shaped profiles for increased versatility.

Each die is designed based on the tube profile, taking into account the diameter, wall thickness, and material to ensure precise and flawless bending.

Operation and Features

The die determines the tube's bend inside the machine, controlling:

- Tube section and diameter

- Bend radius

- Bending precision and stability

The clamping system ensures maximum grip, reducing deformation or ovalization.

Finishing and Testing: Quality Without Compromise

All our dies undergo stringent testing to verify:

- Dimensional precision

- Uniformity of the bend

- Durability and long-term resistance

We offer various finishes, ensuring functional and long-lasting components.

Custom Design and Manufacturing

We provide fully customizable solutions based on production needs and the machine used. Our technical department is available to design and create custom dies, optimized for every type of tube and industrial application.

Pressure Dies and Wiper Dies

Pressure dies and wiper dies are fundamental components in tube bending processes, ensuring precision, quality, and uniformity in the bend

Their correct design and manufacturing allow for impeccable machining, minimizing defects such as wrinkles or deformations.

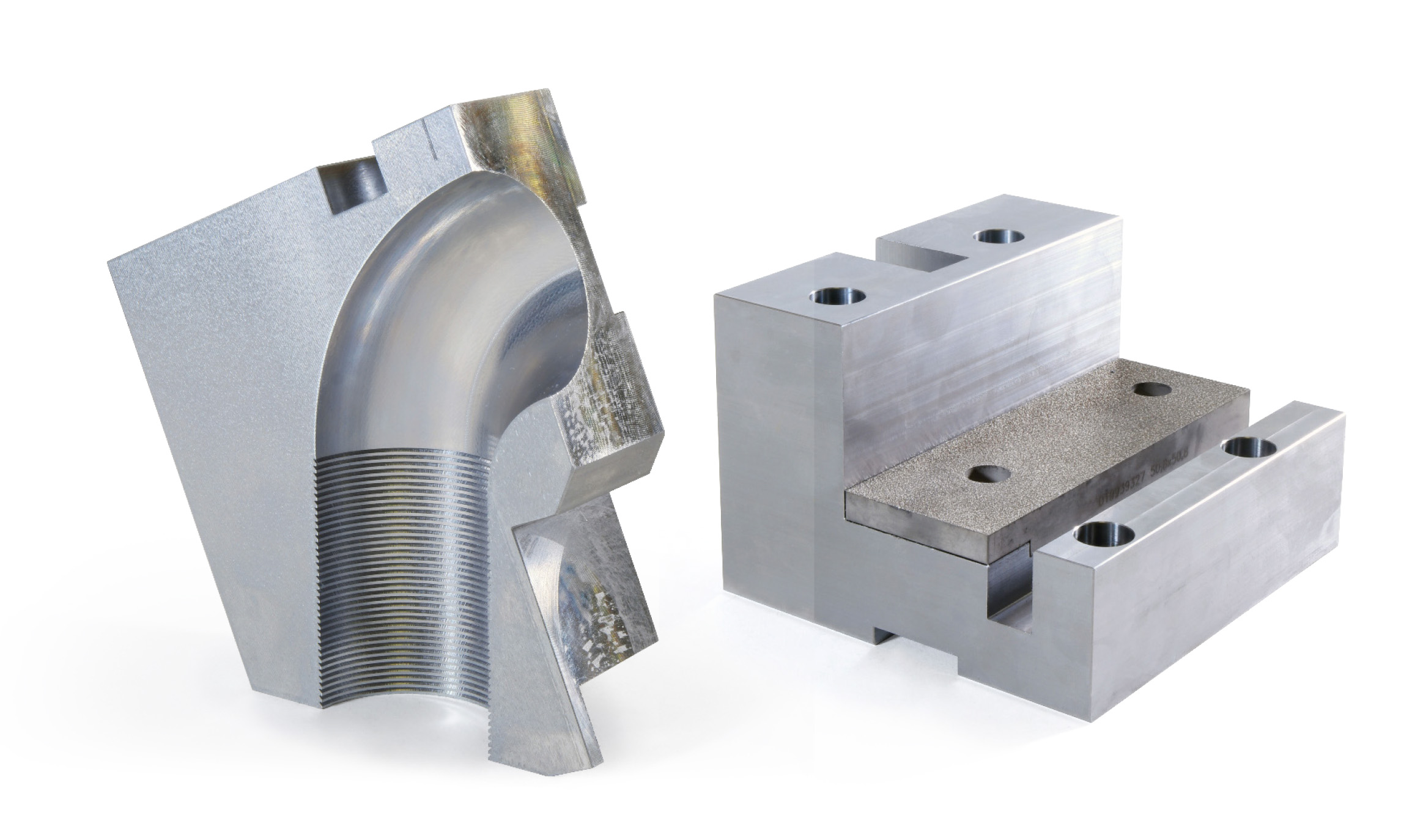

Wiper Dies: no-wrinkles and perfect finish product

The wiper die, also known as an anti-wrinkle die, is an essential component for bending thin-walled tubes with a tight centerline radius.

Its function is to even out the bending area, minimizing imperfections and ensuring a smooth and homogeneous surface.

Types of Wiper Dies

We supply customized Solid wiper Dies, designed to adapt to various processing needs:

- Solid Wiper Dies: Manufactured in a single piece, they guarantee excellent resistance and stability.

- Wiper dies with interchangeable inserts: They offer greater flexibility, allowing for the replacement of the insert without having to change the entire component.

Our Wiper Dies are manufactured using high-strength bronzes and high-quality steels, sourced from the best steel mills, ensuring durability, precision, and reliability.

Pressure Dies: Stability and Precision in Bending

The Pressure Dies is a structural element that opposes the bending force exerted during processing.

Its function is to guide the tube during the process, ensuring maximum precision and reducing the risk of crushing or ovality.

We manufacture custom-made pressure dies, with variable lengths depending on the required bending angle.

Thanks to highly wear-resistant materials and advanced engineering solutions, our Pressure Dies ensure high performance and a long lifespan.

Clamps Die and Clamps

Clamps die and Clamps are essential components in the tube bending, ensuring a stable grip against the die and guaranteeing precision during processing.

Function and Features

These components enhance tube stability during processing and are designed to fit various configurations of tube bending machines. All our clamps undergo rigorous testing to verify:

- Optimized length to ensure a secure grip

- Groove finish, designed to maximize tube adhesion

Available with straight or shaped profiles, our custom clamps are designed to reduce errors and improve the quality of the finished product.

Custom Design and Manufacturing

Thanks to the expertise of our technical department, we create custom solutions for tube clamping in industrial processes.

Each component is carefully designed to ensure high performance and durability.