Best price to quality ratio - delivered

End Forming

End Forming

The use of tools and equipment for tube head deformation allows for a variety of operations: tube widening, tube tapering, flaring, chamfering, deformation for single and double flange fittings, JIC flaring at 37° and 45°, front sealing for hydraulic tubes (ORFS), beading, rolling, and many more. All deformation equipment undergoes thorough testing.

Jaws

Jaws are essential tools for ensuring stability and precision in machining operations. We design and manufacture custom jaws, including straight, shaped, with movable insert, and special models, to meet every application requirement.

Precision and Stability

The use of jaws allows for high-precision machining, ensuring stable and secure clamping. Our clamping systems are made with certified materials and designed to perfectly adapt to the type of processing required.

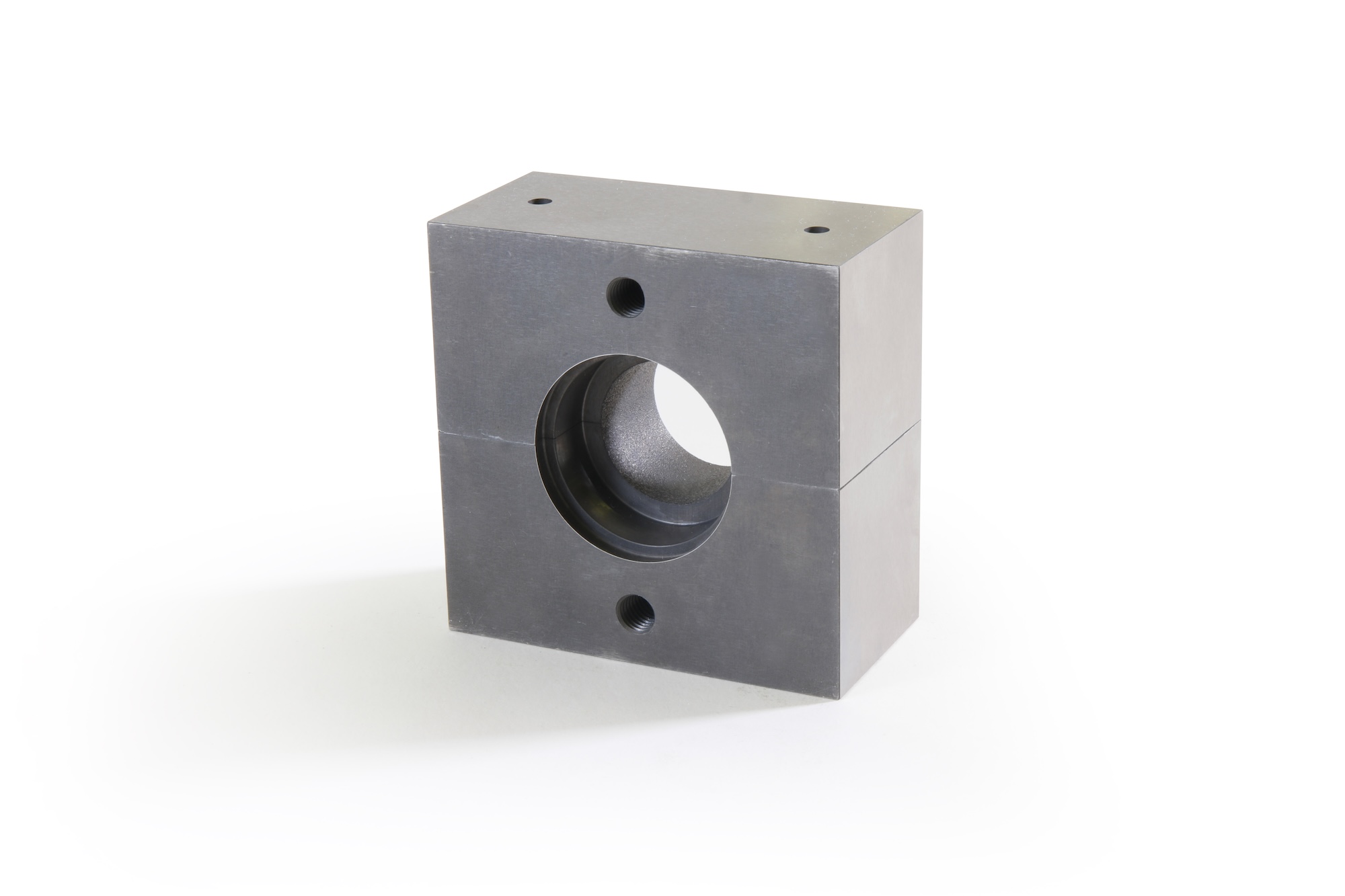

Types of Clamping Dies

- Modular: Composed of multiple elements, offering high versatility.

- Solid: Made of a single block, ensuring maximum rigidity and stability.

Compatibility with Diverse Machining Operations

Jaws are compatible with numerous types of machine and support various production processes. Each clamping system is designed to ensure safety and reliability in machining.

Forming Punches and Fast Tools

Forming punches, standard, elastic or progressive, are essential tools for processing tube ends in a multitude of industrial applications. These components ensure precision and reliability in forming operations.

Customization and Versatility

The custom design of the punches allows for the creation of a wide range of shapes on the tube ends, including calibrations, flares, flanges, and O-ring grooves. This flexibility allows the punches to be used in various manufacturing sectors, including automotive, refrigeration, heating, and aerospace.

Materials and Durability

Each punch is made with high-quality materials, with a careful selection of the steel type to ensure wear resistance and consistent, repeatable production over time.

Progressive Punches

These are special punches that, through their special inner handling system, can manage multiple movements during the processing of the tube. This allows for faster setup during a multi-step end forming.

Compatibility and Precision

Our forming punches are designed for optimal mounting, ensuring perfect integration into the production.

Fast Tools

The Fast Tools holder allows for quick installation thanks to the fixing holes and supplied wrench. The advantages include:

- Fast tool setup that minimizes machine downtime.

- Interchangeability of tools without disassembling the punch holder, thanks to the front fixing.

- Advanced end forming, prepared for potential anti-wear and self-lubricating.

The system is designed to optimize production processes and ensure optimal performance and durability over time. It is also compatible with a wide range of end forming machine brands and models.

Available in two variants:

- FAST00200 processes tubes with a diameter of up to 16mm.

- FAST00100 processes tubes with a minimum diameter of 16mm and a maximum diameter of 40mm.

CUTTING TOOLS

We manufacture blades for orbital and parting-off cutting, designed to ensure maximum efficiency and durability. Each machining operation requires the right cutting tool to achieve precise cutting, shaping, and roughing.

Quality Materials

The use of special steels and optimized coatings ensures high performance on various materials. Our blades guarantee resistance and hardness, meeting the efficiency standards required by the industry.

Precision and Versatility

Designed to offer clean and precise cuts, they improve productivity and the quality of the final result. Every tool we produce is carefully designed to achieve optimal mounting on any type of machine.

Rely on an experienced manufacturer in the design and production of cutting tools.

Rotary Tools

Precision and Innovation

Thanks to these, it is possible to obtain complex geometries that cannot be achieved with traditional pushing equipment.

Design, Quality, and Materials

Our technical department develops customized solutions for every type of machine, to optimize each production phase.

Our equipment is designed to process any type of metal, from steel to copper, as well as aluminum and stainless steel, ensuring maximum quality and resistance thanks to selected materials and targeted heat treatments.

Professional Testing, Impeccable Performance

Each product undergoes rigorous professional testing to ensure high standards of functionality and precision.

We offer production, sales, and technical consulting services, guaranteeing high-performance solutions for the industrial sector.