Model: BS-T44Q-8*1800 Cut To Length Line

BS-ZQ11-8*2400*13000 Steel Plates Diagonally Shearing Production Line

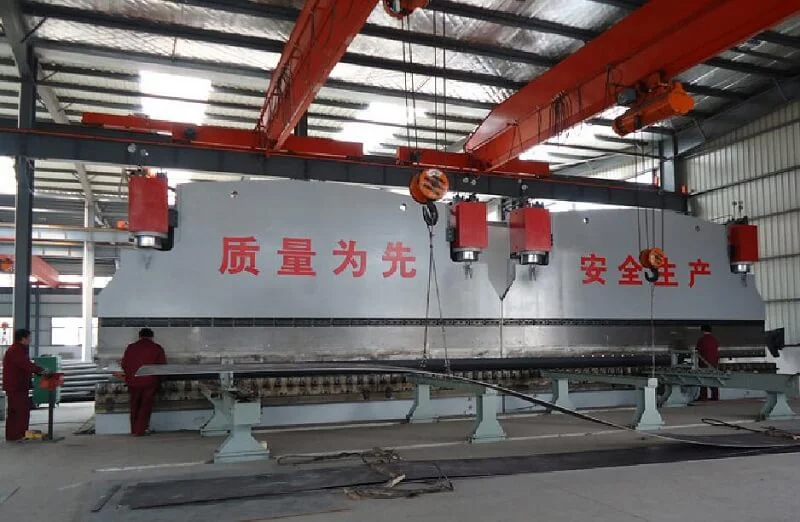

Model: BS-2-WE67K-400/6500 Press Brake(Mechanical Block Cylinder)

Model: BS-HFH400*8-13000 Automatic Welding Production Line

Model: BS-W31Y-600*10 Steel Straightened Machine

Model: BS-WG90*4 Tube Bending Machine

Model BS-DMQG-350 CNC Lamp Door Automatic Plasma Cutting Machine

Model: BS-ZDMJ-350*13000 Automatic Polishing Machine

Model: BS-ZJP-13000 Electrostatic Spraying Production Line

BS-HD120*12 Light Pole Drilling Machine

BS-TRM12 Thread Rolling Machine

BS-KE350S&BS-KE500S Welder

BTSZ-4000/13000 CNC Flame Plasma Cutting Machine