Call us now :

+91 98450 68437

Email us :

skr@techmach.in

sales@techmach.in

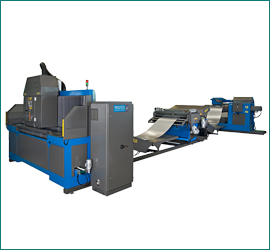

ALPI Venti, with 20 Tonnage of pressing power, is the top model of Produtech punching lines from coil. Thanks to the high flexibility these lines can be installed in many different fields such as: air treatment, roofs and walls production, automotive, silos and metallic structures building, light carpentry, electrical boxes, metallic furniture, perforated sheets and many other products.

An advanced CAD/CAM system allows to pass quickly from the drawing to the finished part.

Working from coil, allows the user to avoid the uneconomical and labor intensive operation to load the single sheets, and guarantee high working autonomy, as well as no limit in the length of the finished parts. Working directly from coil allows the user to save time and money, by eliminating sheet handling and pallet changing; the line can continue to work until there is no material to be punched. The chance to produce from coils already finished along the width allows to reduce the scraps.

Power supply : 380 V – 50 Hz Three phases + G

Motors : Brushless and linear motors

Drive : CNC

Tools number : Up to 20 all indexed with automatic change

Workable width : 1.000 o 1.500 mm

Workable : Max. 4 mm with carbon steel

THICKNESS : Max. 4 mm with stainless steel

Pressing power : 20 Tonnage

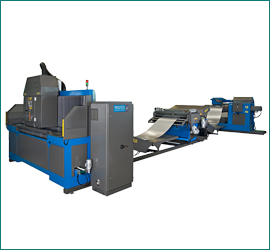

Despite having a working power of 20 Tons, OROBIA is the entry level machine of the punching lines realized by Produtech. It is an economic, simple and rapid machine characterized by a maximum working width of 400mm, the tools are not indexed.

Its main field of use is the lightening industry, the shelving and uprights production, the electrical conduits and more; when the customer needs to produce long narrow parts without the need to rotate to punching tool then OROBIA is the cheapest and perfect solution.

Working from coil, allows the user to avoid the uneconomical and labor intensive operation to load the single sheets, and guarantee high working autonomy, as well as no limit in the length of the finished parts. The user saves also time and money, by eliminating sheet handling and pallet changing; the line can continue to work until there is no material to be punched. The chance to produce from coils already finished along the width allows to reduce the scraps.

The straightening of the material in OROBIA line is realized directly into the punching machine reducing as much as possible the dimension of the line. OROBIA can also be installed in line with rollforming machines to pass quickly from the coil to the finished part.

Power supply : 380 V – 50 Hz Trifase + T

Motors : Brushless motors

Drive : CNC

Tools number : Up to 10

Workable width : max 400 mm

Workable : Max. 4 mm with carbon steel

THICKNESS : Max. 4 mm with stainless steel

Pressing power : 20 Tonnage

ISEO laser collects Produtech’s know how , experienced thanks to the punching lines production, about producing parts directly from coil. The advantages about producing from coil are the chance to obtain finished parts without any limit along the length, the continuous feeding of the laser machine, the high productivity, the possibility to start with a coil already finished along the width minimizing the scraps. Fiber laser technology can add to this advantages a fast and perfect cut obtained also on high reflective materials such as aluminum, brass, copper, with very low consumption and production costs. The new fiber laser technology is very easy, economic and safe to be managed because it doesn’t require the optical path to transmit the laser beam and the focal lens to focus it, so the maintenance costs are eliminated and the costs for wearable parts are really low. The energy consumption is also significantly lower compared to the old CO2 technology.

ISEO laser was studied especially to work on little thickness materials, it is suitable for insulation and ducting field. On little thickness materials the piercing and the cut are fast, also using low power laser sources, this feature makes the production quick and economic.

Power supply : 380 V – 50 Hz Threephases + G

Motors : Linear and Brushless Motors

Drive : CNC

Workable width : max 1500 mm

Workable : Up to 5 mm with carbon steel

THICKNESS : 0,4 / 1 / 2 Kw

Pressing power : 20 Tonnage