Best price to quality ratio - delivered

22501 Machine for feeding trough channels

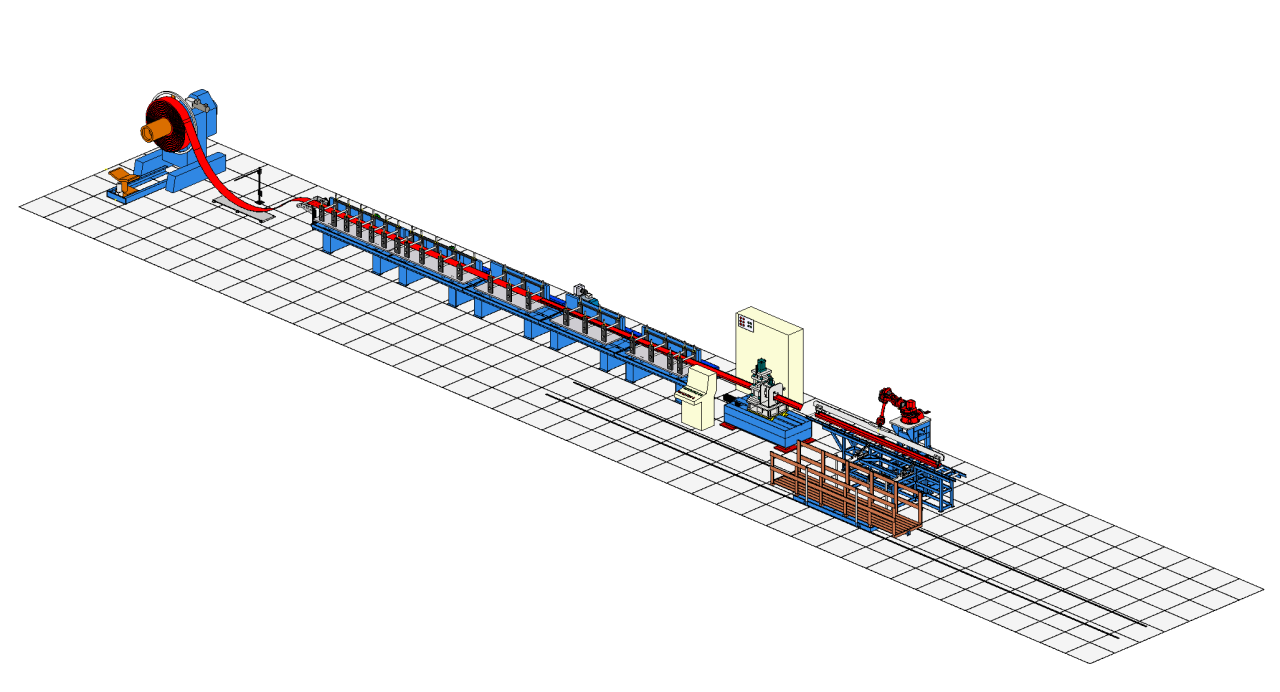

Roll forming line for the production of feeding trough channels.

Technical data

| Decoiler capacity: | 5 ton |

|---|---|

| Material: | galvanized |

| Material thickness: | 1 mm |

| Useful width: | 500 mm |

| Roll forming line speed: | 10 m/min |

Machine configuration

It is a motorized decoiler (or idle on request) with the capacity of 5 tons. Complete with hydraulic power pack and independent electric plant. Hydraulic unit for the spindle regulation, an electric plant for the automatic / manual mode and for the speed regulation. Complete with loop, arm for the loop control, and spokes to maintain the strip in the correct position.

Technical data

| Decoiler capacity | 5 | ton |

|---|---|---|

| Shaft diameter (min/max) | 470/530 | mm |

| Coils maximum external diameter | 1800 | mm |

| Motorized AC decoiler with inverter | 4 | kW |

Roll forming line of high quality, productivity and flexibility. It is characterized by the rapid change of cassettes (it is possible to change the product in a few hours) and materials and finishing rigorously controlled to guarantee for the client more production and less maintenance. It could be completed with sheet lubrication plant, strip introducer and independent regulations for each forming station.

Technical data

| Roll forming line shaft diameter | 50 | mm |

|---|---|---|

| Roll forming line useful width | 500 | mm |

| Roll forming line passages | 24 | n° |

| Material thickness | 0,1 / 1,5 | mm |

It is a set of forming rolls, made of tempered and rectified steel to make the profile required by the customer. The series of rolls is characterized by high precision and durability. Their function is at the heart of the whole plant; for this reason PM follows with particular precision the whole development (the whole process of roll-making is executed internally).

It is in the final part of the line and carries out the flying cut to measure (the roll forming line does not stop). The movement is through a hydraulic unit and electric motor. It includes the final cutting die made especially for the requested profile to have an extremely precise shear without product deformation. This solution increases considerably the productivity.

Final bench used for the unloading and for the stacking of the finished piece lenght 6 m, complete with dedicated robot for unloading and stacking.

The whole electric installation is intended here. Electric cabinet, cable channels, control desk and software for the management of the line parameters, all according to the highest standards of quality and efficiency.

L'impianto idraulico è necessario nelle operazioni di taglio e nelle unità idrauliche di punzonatura o scantonatura. È composto dalla centralina (di potenza tale da soddisfare tutte le lavorazioni), dai collegamenti meccanici (tubature e valvole) e dal software di controllo e gestione.

Series of wire mesh, infrared photocells and sensors for the protection of the operators. They are installed on the line to avoid any accident that could cause physical damages to the operators