Home / Products / SOUL

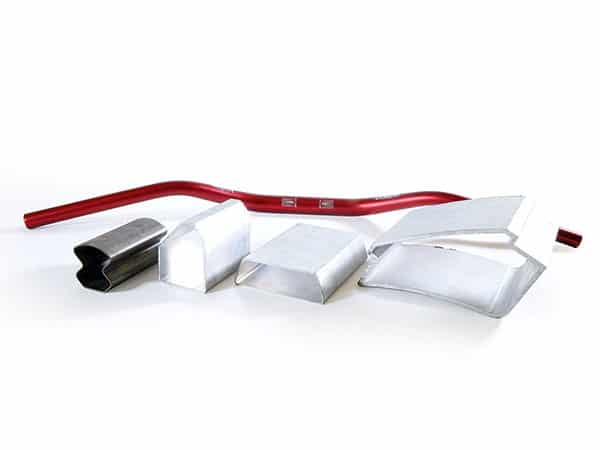

Custom bending cores

Bending cores are an excellent tool for performing bending operations inside thin tubes with very tight radii. In fact, the use of the core allows for extremely careful and precise working processes , remaining inside the tube to be bent in a predefined way, without deforming it.

We deal with the custom production of bending cores with bronze mandrels of different types: mono , omnidirectional and multi-spherical , carefully selecting the material used according to the present processing needs.

In particular, for omnidirectional cores there are three subcategories: standard pitch , close pitch, super close pitch. The core to be used must be selected taking into account the characteristics of the material used and those of the finished product.

Contact us to receive more information and choose the supplies that are right for you, we will support you in every single phase of the sales process.

Higher levels of precision

The use of the core guarantees higher levels of precision in the tube bending operations. Once the bending operation is completed, the core will be extracted without causing any damage or possible deformation to the tube itself, maintaining intact the characteristics that guarantee functionality and aesthetics.