Best price to quality ratio - delivered

Hydraulic Hose Welding

i-ARC400 Power Source

All-around orbital welding power source Specially designed for Huaheng hydraulic hose welding heads, with all power source functions in the market.

Applications

Food Processing Medium Thick Pipe

Chemical Pipe Construction

The iArc400 digital welding power source is designed and manufactured according to advanced technology by Huaheng Welding Co., Ltd.

iArc400 is designed for hydraulic hose pipe welding applications. It is commonly used for chemical, boiler, shipyard, nuclear plant, marine & offshore, and aerospace industries, etc.

Support equipment: Huaheng TC series, TOK series, TOA series, TP060 and TP040 welding head, external wire feeder, GTX series with system updating.

Features

Windows CE embedded version operating system with updatable, simple interface for easy operation;

Up to 20 levels for each program for accurate control according welding requirement.

100 program internal memory storage with external USB support for importing and exporting data.

Real-time welding parameter record during welding process.

Control pendant display for real-time data monitoring.

Adjustable parameter during welding process for some special welding requirements.

Built-in various welding head parameters for accurate motion control.

Water cooling system to ensure long time working.

Perfect fault detection solution, error display, modular design for easy maintenance.

Option to choose offline programming or offline printing.

Solid metal case, optional to use movable trolley for convenient transport

Specification

|

Type

|

Inverter

|

|

Current

|

5 - 400A

|

|

Duty Cycle

|

400A at 60% / 310A at 100%

|

|

Open Circuit Voltage

|

72V

|

|

Input Voltage

|

380V±10% 50/60HZ

|

|

Power

|

13.5KVA

|

|

Display

|

Industrial PC

|

|

Control Function

|

Gas control, Current control, Rotation control, Wire feeding control, AVC control, OSC control, Circuit water control, Fault detection control |

|

Program Storage

|

100

|

|

Numbers of Level

|

20

|

|

Screen

|

6.5”

|

|

CPU

|

1.1G

|

|

Memory

|

1G

|

|

Hard disk

|

2G

|

|

Print

|

Option: printer

|

|

Insulation/Protection Class

|

F / IP21

|

|

Cooling Power

|

800W

|

|

Pump Head

|

40m

|

|

Cooling Tank Capacity

|

15L

|

|

Weight

|

135kg

|

|

Dimension (mm)

|

1110mm ×520mm × 1024mm

|

|

Manufacture Standard

|

GB15579-2004 IEC60974

|

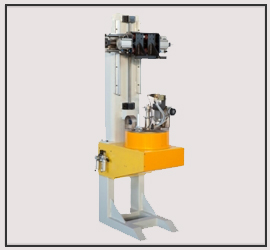

GTX53 Hydraulic Hose Weld Station

Tube to Flange, tube to tube welding expert-welding head Suitable for locomotive, engineering machinery welding.

Applications

Locomotive High-Pressure Hydraulic Pipe

Hydraulic Hose By Orbital Welding

This system is specially designed for tube to flange TIG welding. It can do single position welding or orbital welding, joint or angle welding, with fusion, wire feeding or wire feeding after self-fusion. It canbe placed vertical or horizontal. Support equipment: i-Arc400 Programmable Orbital Welding Power Source. Application: Special tube to tube and tube to flange in locomotive, engineering machinery.

Features

Pneumatic clamping design, convenient and efficient, precisely positioning to ensure the work-piece stable fixed on the platform.

Quick and convenient positioning, no wire wrapping required before welding, reduce preparation time.

Optional to choose with/without wire feeding.

Water circuit cooling torch for long time working.

Specification

| Material | Carbon steel, stainless steel |

| Tube OD(mm) | Φ17~Φ76 |

| Tungsten Diameter(mm) | Φ2.4、Φ3.2 |

| Rotation Speed(rpm) | 0.1~3.29 |

| Torch Angle | 0º~45º |

| Protective Gas | Ar |

| Cooling | Water |

| Cooling Flow(ml/min) | ≥600 |

| OSC Width(mm) | 40 |

| AVC Height(mm) | 40 |

| Wire Diameter(mm) | Φ1.0(standard) |

| Max Wire Feeding Speed (mm/min) | 1800 |

| Weight(kg) | 290 |

| Dimension(mm) | 700×640×1760 |

#634, 3rd cross, HMT layout,

Ganganagar, R T Nagar, Bangalore-560032.

Karnataka State, INDIA.

+91 98450 68437

skr@techmach.in

sales@techmach.in