Best price to quality ratio - delivered

Narrow Gap Pipe Welding

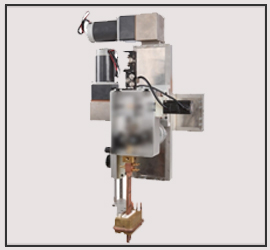

i-Arc401 Power Source

The i-Arc401 programmable welding power source is designed and manufactured according to advanced technology by Huaheng Welding Co., Ltd. Its control system is PC controller, which is open and updatable and embedded in the 32-bit Windows CE operating system. It supports concentrated setting, storing and controlling of all the function parameters.

i-Arc401 is commonly used for thermal power, valve, coal mine machinery, nuclear plant, and boiler, etc.

Features

Windows CE embedded version operating system with updatable simple interface for easy operation

External USB support for importing and exporting data.

Real-time welding parameter record during welding process.

Control pendant display for real-time data monitoring.

Adjustable parameter during welding process for some special welding requirements.

Time & degree switching for welding travel and some relevant parameters.

Built-in various welding head parameters for accurate motion control.

Perfect fault detection solution, error display, modular design for easy maintenance.

Chinese & English user interface.

Real-time monitoring, data sampling, and printing.

Multi-pulse & multi-high frequency.

Option to choose offline programming or offline printing.

Specification

|

Name

|

iArc401

|

|

Type

|

Inverter

|

|

Current

|

5-400A

|

|

Duty cycle

|

400A 60%/310A 100%

|

|

Open Circuit Voltage

|

72V

|

|

Input Voltage

|

3*380V+ 10% 50/60HZ

|

|

Power

|

13.5KVA

|

|

Cooling

|

Air cooling

|

|

Edit

|

PC

|

|

Display

|

Remote controller/Industrial PC/Parameter real-time display in CN & EN

|

|

Program Storage

|

100

|

|

Expert parameter

|

Pre-storage

|

|

Numbers of Level

|

20

|

|

Torch Cooling

|

External water circuit

|

|

Water Tank Type

|

CW-04

|

|

Weight

|

260KG

|

|

Manufacture Standard

|

GB15579- 2004

|

|

Insulation/Protection Class

|

F / IP23

|

|

Dimension

|

710mm*500mm*1500mm

|

i-Arc600 Hot Wire Power Source

Thick-wall tube welding expert in energy industry-power source Suitable for Hot wire TIG welding in energy industry.

The i-Arc 600 hot wire programmable orbital welding power source is designed and manufactured according to advanced technology by Huaheng Welding Co., Ltd. Its control system is PC controller, which is open, updatable and embedded in the 32bit Windows CE operating system. It supports concentrated setting, storing and controlling of all the function parameters.

i-Arc600 is commonly used for thermal power, valve, coal mine machinery, nuclear plant, and boiler, etc.

Features

Intelligent PC control system and world-famous DSP & signal chips, monitoring kinds of output & sampling signals.

Windows CE embedded version operating system with updatable simple interface for easy operation.

Continuous and pulsing for current, rotation and wire feeding.

Real-time AVC control tracking, peak, base, peak & base data.

Record for data adjusting, save data while adjusting in welding process and display comparison of data before and after adjusting.

External USB support for importing and exporting data.

Control pendant display for real-time data monitoring.

Adjustable parameter during welding process for some special welding requirements.

Time & degree switching for welding travel and some relevant parameters.

Accurately set distance between tungsten and work-piece, tungsten would upraise setting distance while touching work-piece. Ignition method optional: high frequency and upraise ignition.

Perfect fault detection solution, error display, modular design for easy maintenance.

Real-time monitoring, data sampling , and printing.

Multi-pulse & multi-high frequency.

Hot wire power source, setting hot wire current independently, increase welding efficiency.

Option to choose offline programming or offline printing.

Specification

|

Name

|

i-Arc600

|

|

Type

|

Inverter

|

|

Current

|

5-600A

|

|

Duty Cycle

|

600A 60%/500A 100%

|

|

Open Circuit Voltage

|

72V

|

|

Hot wire Current

|

5-200A

|

|

Duty Cycle

|

200A 60%/120A 100%

|

|

Input Voltage

|

3*380V+ 10% 50/60HZ

|

|

Power

|

35KVA

|

|

Cooling

|

Air cooling

|

|

Display

|

Remote controller/Industrial PC/Parameter real-time display in CN & EN

|

|

Program Storage

|

100

|

|

Expert Parameter

|

Pre-storage

|

|

Numbers of Level

|

20

|

|

Torch Cooling

|

External water circuit

|

|

Water tank type

|

RC4

|

|

Weight

|

290KG

|

|

Manufacture Standard

|

GB15579- 2004

|

|

Insulation/Protection Class

|

F / IP23

|

|

Dimension

|

810mm*600mm*1700mm

|

TIG 1G/5G Narrow Groove Welding System

Thick-wall tube welding expert in energy industry-welding Head Suitable for thick wall narrow groove welding, with 5-channel water cooling and tungsten swinging.

Applications

Nuclear,Oil and Gas Pipeline

his system is made up of torch angle swinging part, torch fixing part, back protective gas hood, gas hood lifting part, wire feeding frame, camera monitoring system and electric sliding part. The torch fixing part is made by high temperature resistant insulation material, insuring longtime working, and integrated circuit water and protective gas channels. The inner protective gas hood is made up of stainless steel, with water cooling function. The connection part with torch is isolated by insulation material, which can effectively protect the root of pass and external surface while doing groove welding.

Application: Thick work-piece in nuclear facility, chemical, boiler, valve, shipbuilding, power plant, and so on.

Features

Suitable for bevel width more than 9mm narrow bevel welding

Make both sides completely welding by moving of tungsten

High deposition efficiency, low heat input

Welding method: Horizontal, vertical and orbital welding

Special 5-channel water cooling, high duty cycle

Double gas protection, ensuring weld quality

Suitable for carbon steel, stainless steel, nickel base alloy and titanium alloy.

Specification

|

Bevel Type

|

U, J type

|

|

Tube Thickness (mm)

|

30-200

|

|

Bevel Width (mm)

|

9-20

|

|

Max Current (A)

|

350

|

|

Max Wire Feeding Speed(mm/min)

|

5500

|

|

Wire Diameter (mm)

|

1.0-1.2

|

|

Protective Gas

|

Ar 99.99%

|

|

Cooling

|

Water

|

|

Weight (kg)

|

7

|

|

Dimension(mm)

|

175*160*445

|

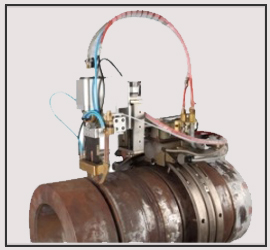

MIG Track Narrow Gap Welding Heads

Thick-wall tube welding expert in energy industry-welding head Suitable for thick-wall narrow groove welding, with wire swinging.

Applications

Nuclear,Oil and Gas Pipeline

This system is made up of a narrow groove MIG welding head, manipulator, positioner and MIG Programmable orbital welding power Source, controlled by PLC.

This system is suitable to bevel depth of 250mm narrow groove welding(width 9~12mm, inclined 1/100~2/100 I bevel), make both bevel sides penetrated by wave wire.

Application: Thermal power, valve, coal mine machinery, engineering machinery, boiler and so on.

Features

Suitable for bevel width less than 9mm narrow bevel welding.

Make both sides completely welding by moving of tungsten.

High deposition efficiency, low heat input.

Welding method: Horizontal, vertical and orbital welding.

Special multi-channel water cooling, high duty cycle.

Double gas protection, ensure weld quality.

Suitable for carbon steel, stainless steel.

Specification

| Bevel Type | U, J type |

| Tube Thickness (mm) | 30-250 |

| Bevel Width (mm) | 9-20 |

| Max Current (A) | 350 |

| Max Wire Feeding Speed(mm/min) | 240000 |

| Wire Diameter (mm) | ¢1.0, ¢1.2 |

| Protective Gas | Mixed gas |

| Cooling | Water |

| Weight (kg) | 5 |

| Dimension(mm) | 320*200*600 |

#634, 3rd cross, HMT layout,

Ganganagar, R T Nagar, Bangalore-560032.

Karnataka State, INDIA.

+91 98450 68437

skr@techmach.in

sales@techmach.in