Best price to quality ratio - delivered

Tube-Tube Sheet Welding

i-Orbital 5000 Power Source

Most functional orbital welding power source Mostly used for tube-sheet welding Suitable for all orbital welding heads of Huaheng, with all available power source functions in the market

Applications

Chemical Pipe Construction

Food Processing Medium Thick Pipe

iOrbital 5000 distributed orbital welding power source is an automatic programmable power source designed by Huaheng. adopting the world’s most advanced technology. This power source is composed of the three following items: power system and control, water cooling tank and integrated truck. This power source has the characteristic of advancement, digitization, intellectualization, generality, and reliability and easy to operate. PC control is adopted for the control system. It is an open and upgradable 32 digits embedded operating system.

This power source is designed for tube/tube, tube to tube/sheet welding. It could be used with all TC products, TOK products, TOA products, TP060/TP040 welding head and external wire feeding machine that manufactured by Huaheng Welding Co., Ltd. It could also be used together with GTX products and other special projects system through upgrade. It usually applies in the tube/tube, tube to tube-sheet welding of chemical industry, food industry, medical industry, electric pipeline, all sorts of heat exchangers, engineering machinery, boiler, military industry and nuclear power industry.

Features

Adopts Windows embedded operating system, easy to operate

Easy to realize USB flash disk program import and export. Easy to replace welding procedure programs. 200 programs of different welding parameters could be stored.

Step rotation for current and wire feeding.

20 levels and the parameters could be changed according to technology requirements. Real time AVC is adopted and three tracking modes which are: peak-value tracking, base value tracking, peak-value and base-value tracking.

Memory function of parameter adjusting is adopted. Easy to store and display the adjusted parameter during the process of welding.

Simulation function is provided during the process of welding. Easy to discover the disadvantages in the actual welding process in advance.

Real time display for the controller. User could view all kinds of states during the process on the controller. The OSC speed, OSC center, OSC width, currentand other welding parameters could be adjusted anytime during the process of welding to meet special requirements.

Time and angle switch can be realized.

Arc ignition current and arc retraction current settings.

Welding voltage/current/distance/degree real time display. Easy to realize automatic attenuation.

Precisely setting for the distance between the tungsten electrode and work-piece. Touch-lift value setup. Two types of arc ignition: high frequency arc ignition and touch-lift arc ignition. Choose one type through programming.

Equipped with water cooling system to make sure the system operate continuously.

Improved failure detection intelligent control.

Chinese/English interface.

Optional off-line programming software is available.

Specification

|

Type

|

Inverter

|

|

Welding Current

|

5~500A

|

|

Duty Cycle(20℃)

|

500A 60% /310A 100%

|

|

Open Voltage

|

72V

|

|

Input Voltage

|

380V±10% 50/60Hz

|

|

Power

|

34 KW

|

|

Display

|

Industry PC

|

|

Control Function

|

Industry PC, Gas control, Current control, Rotation control, Wire feeding control, OSC, AVC, Failure detection intelligent control |

|

Storable Programs

|

100 programs could be stored on other storage devices

|

|

Levels

|

20

|

|

Display Screen

|

10.4”

|

|

Internal Memory

|

4G

|

|

Print

|

Integrate printer

|

|

Water Pump Head

|

30m/0.3Mpa

|

|

Water Tank Volume

|

15 L

|

|

Weight(without refrigerant)

|

110Kg

|

|

Appearance/Dimensions

|

1081mm×990mm×455mm

|

|

Manufacturing Standards

|

GB15579-2004 IEC60974

|

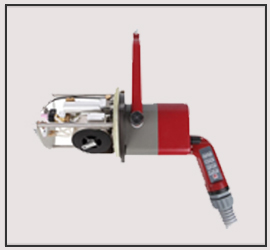

TP8 the Smallest Tube-sheet Welding Head

1st small orbital welding head Min tube OD 8mm; no-twist and AVC track Suitable for protruded, flush, indented tube to tube-sheet Fast fixing, high efficiency.

Applications

Dyeing Tubesheet

Food Processing Heat Exchanger

Pharmacy Heat Exchanger

This welding head is a specially designed TIG welding head for small tube to tube-sheet, suitable for carbon steel, stainless steel, mainly for protruded tube, flush tube and indented tube connection with or without wire feeding. It can weld high protection requirement material such as titanium alloy with tow cover. Support equipment: i-Arc400 Programmable Orbital Welding Power Source. Application: chemical, food, medicine, heat exchanger, power plant, military facility, nuclear facility and so on.

Features

High-precision positioner, fast and accurate, suitable for small heat exchanger.

Auto AVC controlling on or off for manually adjusting.

Water cooled TIG welding head, convenient to change or adjust tungsten.

Integrated wire feeding, 1.0KG wire plate.

No-wire-twist design and special wire feeding design to meet complex single or multi-layer welding requirements.

Buttons on handle, convenient to operate..

Specification

|

Material

|

Carbon steel, stainless steel, titanium alloy(with cover)

|

|

Tube OD(mm)

|

Φ8~Φ32(3/8″~1 1/4″)

|

|

Connection

|

Retract tube, protrusion tube, flush tube

|

|

Rotation Speed(rpm)

|

0.37~7.39

|

|

Arc Adjusting Distance(mm)

|

18

|

|

Max Wire Feeding Speed(mm)

|

1800

|

|

Wire Diameter(mm)

|

Φ0.8

|

|

Protective Gas

|

Ar

|

|

Cooling

|

Water

|

|

Cooling flow(ml/min)

|

≥600

|

|

Duty cycle

|

300A 60%

|

|

Weight(kg)

|

11(no cable)

|

|

Dimension (mm)

|

550×290×510

|

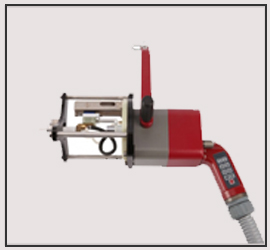

TP040 Fusion Welding Head

Smallest tube to tube-sheet welding head Suitable for tube to tube-sheet fusion welding.

Applications

Air Conditioner Heat Exchanger

Power Plant Condenser

Boiler Heat Exchanger

This is a specially designed TIG welding head for tube to tube-sheet, which is used for carbon steel, stainless steel, mainly for flush tube connection without wire feeding. Support equipment: i-Arc200 and i-Arc400 programmable orbital welding power source. Application: chemical, food, medicine, heat exchanger, power plant, military, nuclear facility, and so on.

Features

Widely used in power plant/condenser stainless steel/titanium alloy tube to tube-sheet welding.

Without wire feeding, small size and light, easy for operation.

Expandable collet positioning design, precise position.

Closed welding achieving perfect welding quality.

N o wire winding, enhanced water cooling system, high duty cycle for long time using.

Specification

|

Material

|

Carbon steel, stainless steel, titanium alloy

|

|

Tube OD(mm)

|

Φ16-Φ38(5/8″-1 1/2″)

|

|

Connection

|

Flush tube

|

|

Tungsten OD(mm)

|

¢2.4

|

|

Rotation Speed(rpm)

|

0.6~12

|

|

Welding Angle

|

0º, 7º option(standard 7°)

|

|

Protective Gas

|

Ar

|

|

Cooling

|

Water

|

|

Cooling Flow(ml/min)

|

≥600

|

|

Rate current

|

100A 60%

|

|

Weight(kg)

|

3.65(no cable)

|

|

Dimension(mm)

|

310×80×165

|

TP060 Most Productive Welding Head

Most popular tube to tube-sheet welding expert Suitable for tube to tube-sheet welding, with self-fusion or wire feeding, AVC tracking and no-twist designing.

Applications

Boiler Heat Exchanger

Pressure Vessel Orbital Application

Petrochemical Heat Exchanger

This welding head is a specially designed TIG welding head for small tube to tube-sheet, suitable for carbon steel, stainless steel, mainly for protruded tube, flush tube and indented tube connection with or without wire feeding. It can weld high protection requirement material such as titanium alloy with tow cover. Support equipment: i-Arc400 Programmable Orbital Welding Power Source. Application: chemical, food, medicine, heat exchanger, power plant, military facility, nuclear facility and so on.

Features

High-precision positioner, fast and accurate, suitable for small heat exchanger.

Auto AVC controlling on or off for manually adjusting.

Water cooled TIG welding head, convenient to change or adjust tungsten.

Integrated wire feeding, 1.0KG wire plate.

No-wire-twist design and special wire feeding design to meet complex single or multi-layer welding requirements.

Buttons on handle, convenient to operate..

Specification

|

Material

|

Carbon steel, stainless steel, titanium alloy(with cover)

|

|

Tube OD(mm)

|

Φ8~Φ32(3/8″~1 1/4″)

|

|

Connection

|

Retract tube, protrusion tube, flush tube

|

|

Rotation Speed(rpm)

|

0.37~7.39

|

|

Arc Adjusting Distance(mm)

|

18

|

|

Max Wire Feeding Speed(mm)

|

1800

|

|

Wire Diameter(mm)

|

Φ0.8

|

|

Protective Gas

|

Ar

|

|

Cooling

|

Water

|

|

Cooling flow(ml/min)

|

≥600

|

|

Duty cycle

|

300A 60%

|

|

Weight(kg)

|

11(no cable)

|

|

Dimension (mm)

|

550×290×510

|

TPN19 Inner Tube-Sheet Welding Head

Most popular inner hole welding expert Suitable for inner hole tube to tube-sheet welding, with AVC tracking and long distance on twisting.

Applications

Boiler Special Heat Exchanger

This welding head is specially designed for inner tube to tube-sheet TIG welding, suitable for carbon steel, without wire feeding. Tube ID should >φ19mm.

Support equipment: i-Arc400 programmable orbital welding power source. Application: petrochemical, boiler, military, nuclear and so on.

Features

Suitable for the heat exchanger inner tube to tube-sheet welding in petrochemical industry.

Minimum inner tube diameter of Φ19mm.

Precise position, easy for operation.

Suitable for carbon steel and stainless steel.

Customization according to specific requirements.

Specification

|

Material

|

Carbon steel, stainless steel

|

|

Tube OD(mm)

|

≥Φ19

|

|

Depth for Inner Tube(mm)

|

20~120

|

|

Tube thickness(mm)

|

1~2.5

|

|

Connection

|

Tube insert, flush tube

|

|

Tungsten Diameter(mm)

|

¢2.4

|

|

Rotation Speed(rpm)

|

0.37~7.39

|

|

Arc adjusting Distance(mm)

|

15

|

|

Protective Gas

|

Ar

|

|

Cooling

|

Water

|

|

Cooling Flow(ml/min)

|

≥600

|

|

Weight(kg)

|

11(no cable)

|

|

Dimension(mm)

|

570×290×510

|

TPN25 Inner Tube-Sheet Welding Head

Most popular inner hole welding expert Suitable for inner hole tube to tube-sheet welding, with AVC tracking and long distance no-twisting.

Applications

Boiler Special Heat Exchanger

This welding head is specially designed for inner tube to tube-sheet TIG welding, suitable for carbon steel, stainless steel, fusion, wire feeding or wire feeding after self-fusion. Tube ID should >φ25mm.

Support equipment: iArc400 Programmable Orbital Welding Power Source. Application: Boiler, heat exchanger, military, power plant, petrochemical and so on.

Features

Inner hole with wire feeding, meet various process requirements.

No-wire-twist design and special wire feeding design to meet complex single-or multi-layer welding requirements.

Auto AVC controlling on or off for manually adjusting.

Specially made water cooling construction.

Wire feeding with no twisting, with integrated wire feeding, 1.0KG wire spool.

Specification

|

Material

|

Carbon steel, stainless steel

|

|

Tube OD(mm)

|

≥Φ25

|

|

Depth for Inner Tube(mm)

|

20~80

|

|

Connection

|

Tube insert, flush tube

|

|

Tungsten Diameter(mm)

|

¢2.4

|

|

Rotation Speed(rpm)

|

0.37~7.39

|

|

Arc adjusting Distance(mm)

|

15

|

|

Max Wire Feeding Speed(mm/min)

|

1800

|

|

Tungsten Diameter(mm)

|

¢0.8

|

|

Protective Gas

|

Ar

|

|

Cooling

|

Water

|

|

Cooling Flow(ml/min)

|

≥600

|

|

Weight(kg)

|

12(no cable)

|

|

Dimension(mm)

|

570×290×510

|

TPS25 Header Box Tube-sheet Welding Head

Most Popular Header Box Welding Expert Suitable for Header Box tube to tube-sheet welding, with AVC tracking and long distance on twisting.

Applications

AC Header Box

This welding head is specially designed TIG welding head for header box tube to tube-sheet. It can weld carbon steel, stainless steel, and indented/flush tube to tube-sheet connection. And its suitable tube diameter is Φ25mm and Φ32mm with wire feeding or self-fusion.

Support equipment: iArc400 Programmable Orbital Welding Power Source.

Application: Boiler, heat exchanger, power plant, petrochemical and so on.

Features

Suitable for the special heat exchanger in chemical industry, e.g. air cooler with hydrogenation..

Perfect solution of deep hole welding with wire feeding.

Narrow space for welding with screw thread hole to reach depth of 120~230mm.

Customization according to specific requirements.

Torch angle negative degree application.

Specification

|

Material

|

Carbon steel, stainless steel

|

|

Tube OD(mm)

|

Φ25 or Φ32

(standardΦ25)

|

|

Max Depth for Inner Tube(mm)

|

230(including plate thickness)

|

|

Connection

|

Flush tube

|

|

Tungsten Diameter(mm)

|

¢2.4

|

|

Rotation Speed(rpm)

|

0.37~7.39

|

|

Torch Angle

|

-3°

|

|

Arc adjusting Distance(mm)

|

18

|

|

Max wire feeding Speed(mm/min)

|

1800

|

|

Tungsten Diameter(mm)

|

¢0.8

|

|

Protective Gas

|

Ar

|

|

Cooling

|

Water

|

|

Cooling Flow(ml/min)

|

≥600

|

|

Duty Cycle

|

200A 60%

|

|

Weight(kg)

|

13(no cable)

|

|

Dimension(mm)

|

780×290×310

|

M90 MAG Tube-sheet Welding Head

1st no-twist wire feeding for MAG tube to tube-sheet welding Auto High efficiency.

Applications

Boiler Heat Exchanger

Warmer MAG Tube Sheet

This is a specially designed automatic MAG tube to tube-sheet welding system for engineering machinery sleeve. It is fixed by positioner, 3D manipulator or intelligent spring balancer, wide range of localization. It is the first no-twist design for MAG tube to tube-sheet system, smooth in wire feeding, convenient and fast. Application: Boiler, engineering machinery, and so on.

Features

Suitable for engineering machinery sleeve welding, boiler tube to tube-sheet and boiler pull bar MAG welding.

Localizer for wide range positioning.

No-wire-twist design and special wire feeding design to meet complex single-or multi-layer welding requirements.

Auto swing during welding.

Pneumatic locking on manipulator for up/down and left/right moving.

15~20KG wire feeding plate, wire diameter:φ1.0 &φ1.2.

Specification

|

Material

|

Carbon steel

|

|

Tube OD(mm)

|

Φ38 ~ Φ260

|

|

Rotation speed(rpm)

|

0.23~4.6

|

|

Torch Angle

|

0°~60°

|

|

Protective Gas

|

Ar

|

|

Cooling

|

Water

|

|

Cooling Flow(ml/min)

|

≥600

|

|

Duty cycle

|

320A 60%

|

|

OSC Width(mm)

|

40

|

|

Manual Adjusting Height (up & down) (mm)

|

40

|

|

Wire Diameter(mm)

|

Φ1.0, Φ1.2(standard)

|

|

Weight(kg)

|

15(no cable)

|

|

Dimension(mm)

|

700×250×240

|

#634, 3rd cross, HMT layout,

Ganganagar, R T Nagar, Bangalore-560032.

Karnataka State, INDIA.

+91 98450 68437

skr@techmach.in

sales@techmach.in