Best price to quality ratio - delivered

EM80

Description

The EM80 is a turntable transfer machine which can be easily set up with a variety of tools depending on the machining process. It offers easy to program features and highly productive output. It is designed for continuous, even unmanned, production of metal parts that are cut to length and then have the ends machined. It is perfect for high volume automotive or agricultural components and for pneumatic or hydraulic fittings.

- Chamfering

- Facing

- turning

- threading

- axial drilling

- CNC turning

For materials with hardness up to 1200N/mm² we recommend Cermet cutting tools. The EM80 machining centre is widely used for automotive components (suspension spacers, anti vibration bushes, engine support, steering columns, etc.) for motorcycle (chain rollers, shock absorber lining, cylinders barrels, hubs, etc.) precision components (bearing, rollers, pump and engine shafts, bolts, nits).

Solutions

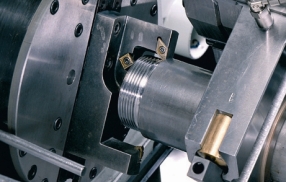

Ends machining 3D heads

Complex profiles turning operations are made possible by the adoption of three axis self-balancing CNC controlled Radial Movement Heads. These ADIGE-SYS patented devices are able to move along three rigidly interpolated axes and can be installed at both sides of a machining station, to operate at one or both ends of the parts

The bundle loader has a lifting capacity of 4,000 kg and can be loaded at any time, allowing the production to continue without interruptions. The single bar of length up to 6.5 m (optionally 8.5 m or 12 m) is automatically loaded and fed to the trim cut position.

Bundle loader

Finished parts unloading

A conveyor brings the finished parts toward a two position deviator-chute. When the front bin is full (the number of parts can be specified in the user-program), the deviator-chute automatically switches its position to allow the parts to drop into the rear bin (and vice-versa). The operator has the time to empty the filled-up bin, without loosing any production time.

Any production can be length measured and certified. The parts which are requested to be length inspected, are measurable by mounting on top of the normal operating units two measuring heads holding two adjustable probes which can cover the entire range of part diameters.

UNIVERSAL MEASURING PROBES

Applications