Best price to quality ratio - delivered

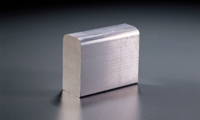

CM601

Description

ADIGE's fifty years experience in cold saws for tubes and bars ensures higher precision cuts at lower manpower and operating costs. Cold saw offer higher performances and advantages compared to conventional ones (like band saws, etc.). Consistent accuracy and precision, higher squareness and cutting quality, higher productivity and reduced bar scrap. All ADIGE cold saw equipment can be supplied with special configurations to meet customer's need. CM601 is an automatic CNC cold sawing machine for medium and short tube and solid bar (single or twin) equipped with CNC control. All adjustments are fast and centralised. Cutting operations are fully automatic and programmable: loading, pre-loading, cutting and unloading in two alternative positions. Cutting capacity is up to O.D. 102mm or O.D. 70 x 70mm (90x90 mm for Aluminum) for a maximum length of 800mm. A new advanced loading system continuously controls each bar which is never in a free fall and is deposited in the feed zone without scratches or surface damages. Loaders are available for bars, for bundles of tubes and for inclined planes, in various lengths.

Main features of the CM601 CNC sawing machine:

- blade-guide device

- cutting precision

- high production

- very fast set-up

- automatic management of the technological cutting parameters directly from the controls

- strong cutting head

- reduced scraps

- extremely clean cutting area

- optimal use of blade

- aluminum: Adjustable cutting speed up to 4.000 m/min with carbide cutters

- brass: available in twin bar and three bar configuration

Solutions

Automatic loading of special profiles while maintaining their orientation

CM601, the automatic sawing machine can be equipped with a fully automatic step loader to achieve non stop production. Productivity of the CM601 for mild steel, hard alloys, aluminium, copper, brass and ECOBRASS® is much higher compared to other similar machines available on the market.

Available in option :

- bundle Loader 3500 - 4500 - 6500 mm

- step by step loader 4500 - 6500 mm

- double-bar configuration

- aluminum option (cutting head from 11 kW)

- hard metal option

Applications