Best price to quality ratio - delivered

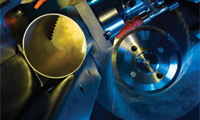

TS72

Description

The TS72 CNC cutting line is able to cut four different programmable lengths out of the same bar unloading in 4 different positions. Brush de-burring, in-line measuring, washing systems and collecting devices are fully integrated. All adjustments are CNC programmable as well as the working cycle starting from a bundle loader (up to 4.000 kg), with bar selection, cutting and unloading. TS72 has a capacity of O.D. 8mm to 102mm with a max. cutting length configuration of 1500 - 3000 - 4500 mm.

- One CNC programmable length stop provide the best material optimization of 4 different length cuts out of a single bar.

- Automatic and efficient programming not depending from the operator's skills.

- TS72's programming selects for the operator the optimum working parameters for the best possible machine performance, from a complete and proven technological database covering blade speeds and feeds for differing materials, saw blade selection and material feed.

- The cutting head construction with hardened and ground helical gears and automatic backlash compensation guarantees longer blade life and its full exploitation, low noise levels and the very best cut quality.

- The material feed system and vice geometry assure the most positive clamping of the material during the cutting cycle whether the material is thin wall delicate tube or tough thick wall tube.

- During the material feeding process, the material is lifted away from the vice bed and vice jaws to prevent the material surface being marked or scratched.

- Blade life, even under arduous cutting conditions, is much improved by micro-lubrication and by turbo refrigeration.

The TS72 cutting line has been designed to operate either as stand alone system or fully integrated in a complete automatic line controlled by one CNC programming unit integrating all additional de-burring, washing, drying and collecting operations.

Solutions

Automatic brush deburrer ST661

External measurement unit MT 100

Automatic steel brush deburrer for both tube ends. Available fully inter-linked with the cutting line or in a stand alone configuration.

Main features:

- Solid and robust structure to minimize vibrations.

- O.D and I.D. deburring of different sections (round, square, rectangular, oval etc)

- Brush wear compensation

- Available with air blower device

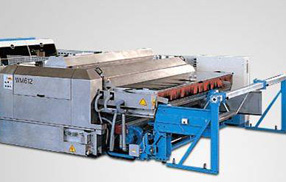

Washing and drying system for internal and external tube cleaning. Available fully inter-linked with the cutting line or in a stand alone configuration.

Main features:

- stainless steel tunnel with thermal insulation and high pressure detergent water

- program tube length adjustment

- linkable to a full y automatic production line

Automatic Washing & Drying System WM612

Automatic tube collecting device RT711

Automatic tube collector directly linkable to ADIGE's saws, deburrer and washer. Tubes are automatically collected and stacked.

Main features:

- Tubes can be stacked in open or closed bins.

- Dramatic noise reduction.

- Tube surface and ends are preserved from scratches or impact damages.

- Easier tube handling for further operations.

Washing and drying system for internal and external tube cleaning. Available fully inter-linked with the cutting line or in a stand alone configuration.

Main features:

- Automatic management of different pallet styles (up to 10 at the same time) to unload different cut lengths.

- Automatic management of the multiple unloading configurations (up to 10) and correct pallet positioning check.

- Easy programming via the intuitive and comprehensive operator interface.

- Storage and graphic display of the pallet's content status.

Palletizing system RT100

Applications