Best price to quality ratio - delivered

LT9

Description

The LT9 is an automatic modular plant designed for steel sheet cutting featuring excellent dynamic performance. The use of linear motors guarantees performance levels that put the LT9 in direct competition with the best systems present on the market. The LT9 can be equipped with either CO2 sources or the new fiber sources. Thanks to its modular structure, according to the materials and applications required, the LT9 can be configured in the most convenient and profitable manner.

Performances:

Very good-quality cutting of mild steel up to 20 mm thickness. High-speed cutting of aluminium (series 6060 and 1050) and stainless steel.Cutting of copper and brass up to 5 mm thickness.

Large formats:

Processing of large format steel sheets with configurations up to 3000 x 9000.

Cutting parameters:

The cutting technology included in the database parameters that comes with the LT9 system is the result of over ten years of experience in laser cutting of the BLM GROUP technicians.

Unmanned processing:

Automatic loading and unloading systems guarantee the possibility of working through a night shift unattended.

Solutions

Top-notch productivity with automatic loading and unloading systems

Optical path (only CO2 version):

The optical path of the beam is pressurized and offset in length to ensure uniformity of performance throughout the operating range.

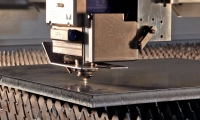

Focusing head:

it is equipped with autofocus and lens powered automatic repositioning.

Steel sheet detection:

the position of the steel sheet on the work surface is detected automatically by a laser rangefinder.

Fume suction: a system with separate chambers allows to optimize the suction along the entire work surface.

Active piercing: control device designed to optimise the piercing phase. The laser source is self-driven to obtain the best piercing quality in the shortest time possible. Head equipped with sensor: In the CO2 configuration the head can be optionally equipped with sensors for monitoring the state of the lens, the temperature of the various components of the focusing head and the quality of the cutting process during processing

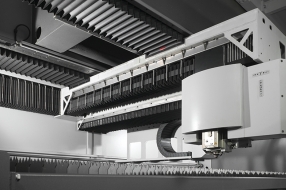

Ragno speed:

the automatic loading and unloading system of the "Ragno Speed" sheet gives the plant the feature to carry out a full night processing cycle unattended.

Hive:

additional material loading capacity can be added by integrating up to two storage-towers equipped with trays that can hold 300 kg. each The number of trays can be customized according to the height available.

Optimal accessibility and easy scrap management

Why An Lt9

- LT9 shares the same programming interface and the same production management tools available on all other BLMGROUP laser machines.

- Using it in combination with any other BLM GROUP machine, it is possible to take advantage of a unique planning approach and optimization of the production process.

Applications