Best price to quality ratio - delivered

AST30

Description

AST30 is a tube end-forming & machining center with 6 working stations, one could be rotary, suitable for machining and end-forming operations. Each of the 6 forming stations can be used and programmed for end-forming such as expansion, reduction, rolling, doming trimming and automatically process both ends of the tube in one cycle through auto loader. The PLC control unit programmes the two axes of the machine for maximum efficiency without requiring manual adjustments. Automatic loading and unloading devices increase quality and consistency of the AST30 tube machining and end-forming machine.

Solutions

Load / Unload

Thanks to the wide range of loading devices customers can choose the best solution for their needs. Following are the main features of our handling systems:

Load / Unload

- multiradii (up to 8 tools)

- Special pneumatic loader with double clamp for the simultaneous load/unload. The loading cycle is contemporary to the machine cycle.

- High-range automatic loader

- Loading device for the sequential loading of both tube ends in automatic

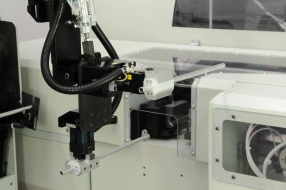

- Robots, manipulators, vibrators for the loading of bushes

- Integration in manufacturing cells with bending stations connected by means of robots

- Automatic collecting systems on wheels

Process

Process aimed to produce steel oil level dip stick (Ø 10x1mm) for the automotive industry

and consisting of the following operations:

- feeding from coil

- straightening

- end-forming of tube end n. 1

- swarfless cut

- end-forming of tube end n. 2

- bending with variable radius

- automatic unload

The advantages of this configuration:

- cycle time reduced by 2/3 for each piece,

- production quality remains the same over three working shifts, independent from operator's skills

- only one supervisor required over three shifts

Applications