Best price to quality ratio - delivered

TUBE-FORM ELE

Description

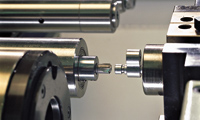

TUBE-FORM ELE is a fully electric CNC range of machine for combined tube end operations on tube O.D. 50mm max. ALL machine movements are electrically programmed and driven (including power control and modulation of the ram tool) assuring tight accuracy and absolute consistency. Its modular design allows to organise the most suitable process flow according to the required tool and final job.

Main features:

- Up to 6 ram stations

- Full combination of ram and rotary tool operations

- Available machining & forming operations: de-burring - beading - expanding - facing - threading - rolling - friction welding - machining - cutting - milling

- The cutting head construction with hardened and ground helical gears and automatic backlash compensation guarantees longer blade life and its full exploitation, low noise levels and the very best cut quality.

- multiradii (up to 8 tools)

- Special pneumatic loader with double clamp for the simultaneous load/unload. The loading cycle is contemporary to the machine cycle.

- High-range automatic loader

- Loading device for the sequential loading of both tube ends in automatic

- Robots, manipulators, vibrators for the loading of bushes

- Integration in manufacturing cells with bending stations connected by means of robots

- Automatic collecting systems on wheels

- Execution of complex profiles

- Enhanced repeatability and accuracy (guaranteed tolerance ± 0,05mm)

- Reduced changeover time (-50%)

- Tool change and parameter reset in less than 5 minutes

All operations are fully CNC programmable (up to 8 controlled axis). This avoids manual operations with substantial savings in cycle times and loading and unloading operations with increased benefits in quality and work repetition.

Solutions

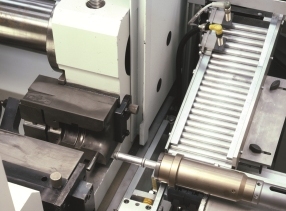

Load / Unload

Thanks to the wide range of loading devices customers can choose the best solution for their needs. Following are the main features of our handling systems:

Load / Unload

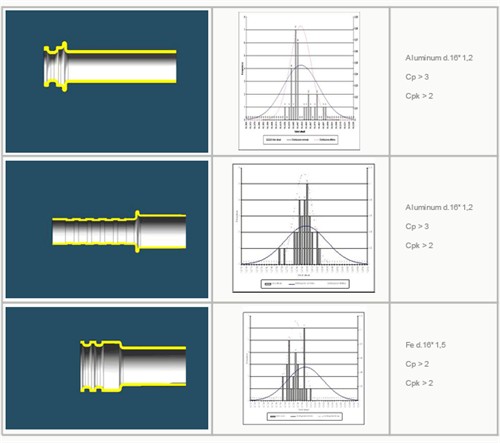

Accuracy and repeatability of the end-forming process

Thanks to the "all electric", you can install the independent rotary mandrel (RGL31) for rolling processes with the following results