Best price to quality ratio - delivered

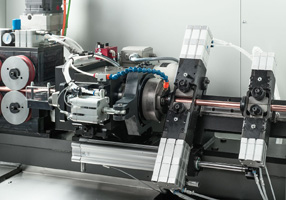

TUBE-FORM with rotary table

Description

Main features of TUBE-FORM with indexing rotary table are:

- 8 tons

- four auto-indexing clamping stations

- up to 6 forming stations and two supplementary rotary stations (for rolling and/or machining)

- unique 'floating' clamp jaw compensates for tube intolerances

- higher productivity with the loading and unloading time absorbed into the cycle time

- each of the four clamping stations can take more than one tube enhancing output

- nuts, flanges and fittings can be easily accommodated and loaded manually or automatically

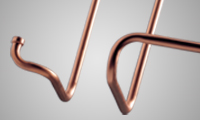

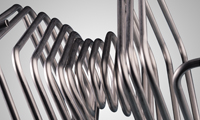

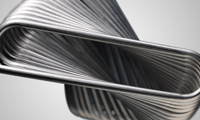

The CNC tube end-forming machine TUBE-FORM is ideal for components which require both ends end-formed and for short or complex pre-bent parts which are difficult to load and unload.

Solutions

Cutting devices

According to the applications, the machine may be configured with different cutting devices:

- Inner orbital cutting - for pre-etching the tube for piecing at the end of the bending process.

- Outer orbital cutter - this tool is managed by two electric axes for faster speed and better cutting quality.

- Both devices are recommended for applications in which the production of chips is not desirable.

- Disc cutter - this is managed by one electric axis recommended for applications privileging speed and flexibility.

Applications