Best price to quality ratio - delivered

Medium Wall Pipe Welding

i-ARC400 Power Source

Most functional orbital welding power Source Mostly Used for Pipe Welding Suitable for Huaheng all orbital welding heads, with all power source functions in the market.

Applications

Food Processing Medium Thick Pipe

Chemical Pipe Construction

The iArc400 digital welding power source is designed and manufactured according to advanced technology by Huaheng Welding Co., Ltd. The power source is made up of controller, power supply and water cooler.

iArc400 is designed for medium and thick-wall pipe to pipe welding applications. It is commonly used for chemical, boiler, shipyard, nuclear plant, marine & offshore, and aviation aerospace industries, etc. Support equipment: Huaheng TC series, TOK series, TOA series, TP060 and TP040 welding head, external wire feeder, GTX series with system updating.

Features

Windows CE embedded version operating system with updatable, simple interface for easy operation;

Up to 20 levels for each program for accurate control according welding requirement.

100 program internal memory storage with external USB support for importing and exporting data.

Real-time welding parameter record during welding process.

Control pendant display for real-time data monitoring.

Adjustable parameter during welding process for some special welding requirements.

Built-in various welding head parameters for accurate motion control.

Water cooling system to ensure long time working.

Perfect fault detection solution, error display, modular design for easy maintenance.

Option to choose offline programming or offline printing.

Solid metal case, optional to use movable trolley for convenient transport

Specification

|

Type

|

Inverter

|

|

Current

|

5 - 400A

|

|

Duty Cycle

|

400A at 60% / 310A at 100%

|

|

Open Circuit Voltage

|

72V

|

|

Input Voltage

|

380V±10% 50/60HZ

|

|

Power

|

13.5KVA

|

|

Display

|

Industrial PC

|

|

Control Function

|

Gas control, Current control, Rotation control, Wire feeding control, AVC control, OSC control, Circuit water control, Fault detection control |

|

Program Storage

|

100

|

|

Numbers of Level

|

20

|

|

Screen

|

6.5”

|

|

CPU

|

1.1G

|

|

Memory

|

1G

|

|

Hard disk

|

2G

|

|

Print

|

Option: printer

|

|

Insulation/Protection Class

|

F / IP21

|

|

Cooling Power

|

800W

|

|

Pump Head

|

40m

|

|

Cooling Tank Capacity

|

15L

|

|

Weight

|

135kg

|

|

Dimension (mm)

|

1110mm ×520mm × 1024mm

|

|

Manufacture Standard

|

GB15579-2004 IEC60974

|

TOK Series Pipe Heads

Open tube to tube weling expert-Orbital Welding Head Suitable for wall thickness ≤ 4mm tube installation, wide range of welding with touching tracking.

This welding head is special designed for wall thickness ≤4mm tube to tube TIG welding, suitable for carbon steel, stainless steel tube to tube connection, mainly for wire feeding or self-fusion. Support equipment: i-Arc200 and i-Arc400 Programmable Orbital Welding Power Source. Application: chemical, food, medicine, engineering installation, boiler, military, nuclear plant, and so on.

Features

Suitable for thin wall thickness carbon steel, stainless steel tube or pipe orbital welding;

Suitable for connection of tube to tube, tube to flange, tube to elbow, tube to valve and so on;

Automatic all position TIG tube to tube welding with/without wire feeding;

Water circuit cooling, achieving long time working;

Mechanical profile tracking design, ensure seam quality.

Specification

| TOK43 | TOK77 | |

|

Material

|

Carbon steel, stainless steel

|

Carbon steel, stainless steel

|

|

Tube OD(mm)

|

Outer clamp:Φ15~Φ25 (5/8″~1″)

|

Outer clamp:Φ19.05~Φ45(3/4″~1 3/4″)

|

|

Inner clamp:Φ25~Φ43 (*1″~1 5/8″)

|

Inner clamp:Φ45~Φ77 (1 3/4″~3″)

|

|

|

Tungsten diameter(mm)

|

Φ2.4

|

Φ2.4

|

|

Rotation speed(rpm)

|

0.37~7.45

|

0.19~3.8

|

|

Protective gas

|

Ar

|

Ar

|

|

Cooling

|

Water

|

Water

|

|

Cooling flow(ml/min)

|

≥600

|

≥600

|

|

Dimension(mm)

|

|

|

|

A

|

128

|

180

|

|

B

|

115

|

120

|

|

C

|

85~92

|

95~101

|

|

D

|

165

|

92

|

|

E

|

44

|

82

|

|

F

|

230

|

290

|

|

Weight(kg)

|

2.5(no cable)

|

4.0(no cable)

|

|

Dimension(mm)

|

305×128×230

|

310×180×290

|

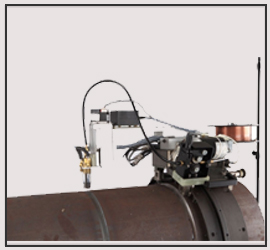

MIGTRACK60 Pipe Heads

This system is specially designed for pipe to pipe automatic MIG welding, could do root, filling, covering passes welding for OD > φ300mm pipe.

Support equipment: PHOENIX COLDARC series welding power source.

Application: Engineering liquefied gas and oil pipe installation and factory prefabrication.

Features

Gear transmission, stable rotation speed.

Special MAG double root pass process, satisfying complex work conditions.

Double water cooling, suitable to big and thick pipe filling pass process.

Short distance wire feeding, ensure stable wire feeding.

Different guides to do welding for different OD tubes.

Specification

| Tube OD(mm) | 300-1500(12”-60”) |

| Rotation Speed(mm/min) | 40~500 |

| OSC Width(mm) | 50 |

| AVC Height(mm) | 50 |

| Cooling | Circuit Water cooling |

| Connection | Tube to tube, tube to elbow |

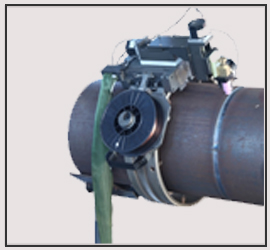

TOA Series Pipe Heads AVC&OSC

Open thick-Wall pipe to pipe weling expert-orbital welding head Suitable for pipe installation, wide range of welding with AVC tracking and OSC covering.

Applications

Food Processing Medium Thick Pipe

Chemical Pipe Construction

This welding head is special designed for pipe to pipe TIG welding, suitable for carbon steel, stainless steel pipe to pipe connection, mainly for wire feeding or self-fusion, option of TB150 integrated wire feeder and HWT10 external wire feeder with AVC & OSC function.

Support equipment: i-Arc400 Programmable Orbital Welding Power Source.

Application: chemical, food, medicine, engineering installation, boiler, military, nuclear and so on.

Features

Suitable for medium wall thickness carbon steel, stainless steel material pipe welding.

Suitable for connection of tube to tube, tube to flange, tube to elbow, tube to valve and so on.

Automatic all position TIG tube to tube welding with/without wire feeding;

Compact structure design, stable rotation with small rotating inertia.

Water circuit cooling, achieving long time working.

Oscillation, multi-passes welding process.

Optional of external/integrated wire feeder.

Specification

|

TOA77

|

TOA130

|

TOA180

|

TOA230

|

TOA320

|

||||||

|

Material

|

Carbon steel, stainless steel

|

|||||||||

|

Tube OD(mm)

|

Inner clamp:Φ19.05~Φ45(3/4″~1 3/4″)

|

Inner clamp:Φ38.1~Φ76(1 1/2″~3″)

|

Inner clamp:Φ50.8~Φ114.3(2″~4 1/2″)

|

Inner clamp:Φ120~Φ178(4 1/2″~7″)

|

Inner clamp:Φ150~Φ230(6″~9″)

|

|||||

|

Outer clamp:Φ45~Φ77(1 3/4″~3″)

|

Outer clamp:Φ76~Φ130(3″~5″)

|

Outer clamp:Φ114.3~Φ180(4 1/2″~7″)

|

Outer clamp:Φ178~Φ230(7″~9″)

|

Outer clamp:Φ230~Φ324(9″~12 3/4″)

|

||||||

|

Tungsten diameter(mm)

|

Φ2.4、Φ3.2

|

Φ2.4、Φ3.2

|

Φ2.4、Φ3.2

|

Φ2.4、Φ3.2

|

Φ2.4、Φ3.2

|

|||||

|

Rotation speed(rpm)

|

0.19~3.8

|

0.11~2.2

|

0.09~1.8

|

0.05~1.0

|

0.026~0.52

|

|||||

|

Protective gas

|

Ar

|

Ar

|

Ar

|

Ar

|

Ar

|

|||||

|

Cooling

|

Water

|

Water

|

Water

|

Water

|

Water

|

|||||

|

Cooling flow(ml/min)

|

≥600

|

≥600

|

≥600

|

≥600

|

≥600

|

|||||

|

OSC width(mm)

|

20

|

40

|

40

|

40

|

40

|

|||||

|

AVC height(mm)

|

40

|

40

|

40

|

40

|

40

|

|||||

|

Wire diameter(mm)

|

Φ1.0(standard)

|

Φ1.0(standard)

|

Φ1.0(standard)

|

Φ1.0(standard)

|

Φ1.0(standard)

|

|||||

|

Max wire feeding speed(mm/min)

|

1800

|

1800

|

1800

|

1800

|

1800

|

|||||

|

Dimension(mm)

|

|

|

|

|

|

|||||

|

A

|

220

|

300

|

375

|

425

|

550

|

|||||

|

B

|

180

|

235

|

285

|

300

|

315

|

|||||

|

C

|

112~132

|

132~172

|

184~224

|

195~235

|

230~270

|

|||||

|

D

|

92

|

165

|

225

|

250

|

297

|

|||||

|

E

|

82

|

132

|

182

|

232

|

328

|

|||||

|

F

|

320

|

400

|

525

|

570

|

680

|

|||||

|

Weight(kg)

|

5.5(no cable)

|

10.8(no cable)

|

19.5(no cable) |

21.5(no cable)

|

36(no cable)

|

|||||

|

Dimension(mm)

|

370×220×320

|

435×300×400

|

445×375×525

|

465×425×570

|

430×610×680

|

|||||

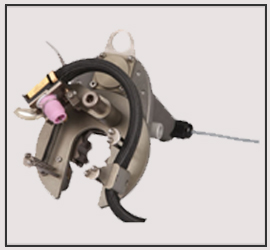

TOA50 Narrow Space Pipe Head

Narrow spacing tube to tube welding expert-orbital welding Head Suitable for narrow spacing tube welding, with AVC tracking and OSC covering.

This welding head is specially designed for tube to U shape tube TIG welding, suitable for carbon steel, stainless steel tube to tube connection, mainly for wire feeding or self-fusion. It is integrated with a wire feeder and with AVC & OSC function.

Support equipment: i-Arc400 programmable orbital welding power source.

Application: chemical, food, engineering installation, boiler, military, nuclear plant, and so on.

Features

Special design for U-shape tube and narrow spacing tube to tube connection.

Integrated orbital welding head and wire feeding.

Unique cable hose twist.

Motorized AVC and OSC motion for narrow spacing application.

Quick launch of clamping device to ensure homocentric.

The most extensive practical experience ensures welding quality and repeatability.

Specification

|

Tube OD(mm)

|

Φ32~Φ51(1 1/4″~2″)

|

|

Tungsten Diameter(mm)

|

Φ3.2

|

|

Wire Diameter(mm)

|

Φ1.0

|

|

Rotation Speed(rpm)

|

0.25~5.02

|

|

Cooling

|

Water

|

|

Dimension(mm)

|

|

|

A

|

128

|

|

B

|

140

|

|

C

|

85~97

|

|

D

|

78

|

|

E

|

59

|

|

F

|

360

|

|

Weight(kg)

|

5

|

TIG Track Pipe Heads

Expert for big pipe to pipe connection Cold wire/Hot wire AVC tracking & OSC covering Suitable for oil pipe, marine, ship, nuclear plant and military applications.

This track welding system is made for big pipe to pipe welding. The system is made up of torch angle swinging part, torch fixing part, back protective gas hood, gas hood lifting part, wire feeding frame, camera monitoring system and electric sliding part. The torch fixing part is made by high temperature resistant insulation material, insuring longtime working and integrated with circuit water and protective gas channels. The inner protective gas hood is made up of stainless steel, with water cooling function. Its connection part with torch is isolated by insulation material, which can effectively protects the weld's root and external while doing groove welding.

Application: Thick work-piece in industries of nuclear plant, chemical, boiler, valve, shipbuilding, motor rotor, and so on.

Features

Suitable for bevel width less than 9mm narrow bevel welding.

Make both sides completely welding by moving of tungsten.

High deposition efficiency, low heat input.

Welding method: Horizontal, vertical and orbital welding.

Special 5-channel water cooling, high duty cycle.

Double gas protection, ensure weld quality.

Convenient to change and maintain consumable parts, less consumables and low cost.

Suitable for carbon steel, stainless steel, nickel base alloy and titanium alloy.

Specification

|

Bevel type

|

U, J type

|

|

Tube Thickness (mm)

|

30-200

|

|

Bevel Width (mm)

|

9-20

|

|

Max Current (A)

|

350

|

|

Max Wire Feeding Speed(mm/min)

|

5500

|

|

Wire Diameter (mm)

|

1.0-1.2

|

|

Protective Gas

|

Ar 99.99%

|

|

Cooling

|

Water

|

|

Weight (kg)

|

7

|

|

Dimension(mm)

|

175*160*445

|

#634, 3rd cross, HMT layout,

Ganganagar, R T Nagar, Bangalore-560032.

Karnataka State, INDIA.

+91 98450 68437

skr@techmach.in

sales@techmach.in