Best price to quality ratio - delivered

LT Fiber

Description

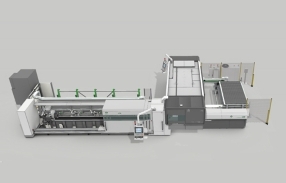

LC5 is the ideal solution for laser cutting both sheet and tubes in all situations in which installing two separate systems is hardly justifiable due to reasons of dimensions, production volumes or more simply cost-effectiveness. A single laser source and a single cutting head is capable of switching from sheet to tube processing (and vice versa) immediately, automatically and without needing re-tooling. LC5 can process metal sheet up to 3000x1500 (or 4000x2000) and round, square, rectangular, oval shaped tubes up to an inscribed diameter of 120 mm and a bar weight of up to 13.5 kg/m. LC5 can be equipped with either a CO2 laser source with a power of up to 4.5 kW or a fiber laser source with power up to 3 kW. The fiber source is advantageous for cutting high reflecting materials (brass, copper) and for more effective aluminium processing. The cutting process is controlled by sensors which monitor all the main parameters on both the CO2 source and fiber versions. The optimal cutting parameters are selected in fully automatic manner according to the material and thickness. Focus is regulated by a servo mechanism fitted inside the cutting head.

Advantages

- tube <> sheet immediate switch

- automatic tube bundle loader

- automatic unloading

- scrap separation

- BLM GROUP 3D graphic CAD/CAM

- tidy collection solutions

Solutions

Top-notch productivity with automatic loading and unloading systems

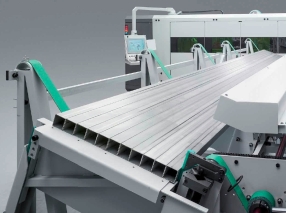

The loader separates the tube from the bundle and handles it without scratching right up to the end of cutting process. The next tube is always ready to be loaded on the loader to minimize the tube loading time.

Large front windows provide convenient viewing of the entire pallet working area and allow to take action promptly for checks on production.

Fully openable doors for optimal access

Access to the tube processing line is facilitated by wide opening doors. This is very convenient for manual loading of single tube whenever required.

Large front windows provide convenient viewing of the entire pallet working area and allow to take action promptly for checks on production.

Everything under control on the double operator panel

Expandable later

An expansion option is provided by the sheet loading and processed sheet pallet changer system. The automatic loading and unloading system can be integrated at a later time and is available for all the machine configurations. Further automation and flexibility can be achieved by adding one or two sheet storage towers on loading and unloading side. This opens the way to full automatic production.

Why a LC5

The advantages of the fiber laser

The possibility of splitting the investment up over time, starting with a sheet machining system and adding the tube machining system only later, makes the LC5 a one-of-a-kind solution on the laser cutting machine market.

CONFIGURABLE

Capable of machining sheet only, sheet and tubes, with in-line or transverse layout and with CO2 or fibre laser technology. Productivity and degree of automation can be increased by implementing automatic stores and feeding towers. The LC5 adapts to all needs making it a rational, adequate investment.

TUBE PROCESSING EXPERIENCE

Tube processing is an area of constant growth. The use of tubes for making automotive chassis and frames and for structural applications is continuously expanding and new areas and new solutions in terms of cost-effectiveness and efficacy are being discovered. Approaching these solutions and opportunities (either now or later) with an experienced partner as BLM GROUP is the best choice.

EASE OF ADOPTION

The machine is compact and integrates all electric components onboard to minimise space and installation time.

Applications