Best price to quality ratio - delivered

LT Free

Description

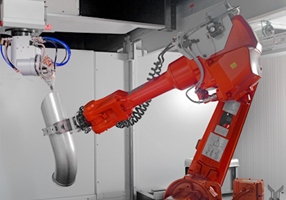

The LT-FREE five-axis laser cutting system is ideal for three-dimensional parts, bent, hydroformed or pre-assembled tubes or flat and pressed sheets. Traditional cutting, drilling, piercing, milling and deburring operations, which are normally carried out in sequence, can now be performed on a single machine in a single cycle. This makes finished parts without 'work in progress' inventory, consequently reducing material handling costs and streamlining the entire production process - as well as downsizing the space needed for storage. The system is equipped with a fibre laser capable of processing any type of metallic components (mild steel, copper, aluminum, brass, stainless steel, galvanized steel, etc.) at high speed with excellent quality.

Possible jobs:

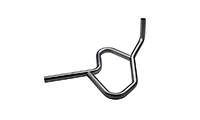

- Trimming and piercing on bends

- High quality and accurate cuts, ideal for welding by robots during a later assembly stage

- Finishing of hydroformed parts

- Piercing anywhere on bent tubes

- Preformed sheet trimming

- Processing of preassembled frames

Solutions

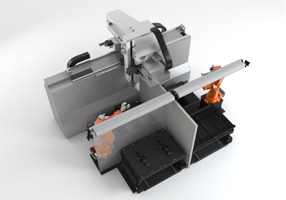

Dual robot station

The dual robot station configuration allows independent loading and unloading without interrupting the laser cutting process hence boosting productivity.

The part is not moved during the cutting operation. In this way, top-notch accuracy is guaranteed by a five-axis system and the flexibility of a robot handling system.

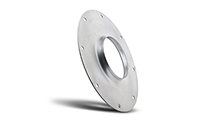

Handling of parts to be machined

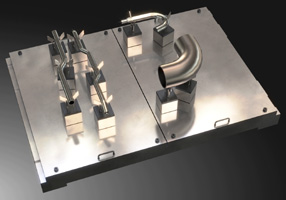

Support tables

No special dedicated locating templates are needed for positioning bent tubes.

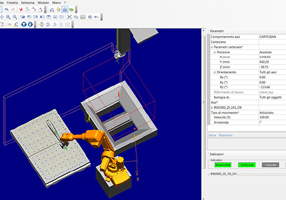

All machine and handling robot cycles can be programmed directly offline using BLM GROUP programming and simulating software. Just select material and thickness: the machine will automatically determine all the cutting parameters and set the optimal focus position.

Software

Cameras

An array of features makes the LT-FREE extremely comfortable to use. Cameras are installed inside the safety enclosure to monitor machine operation.

Why A LT-Free

Saving material

The LT-FREE can make cuts very close to each other. This provides remarkable advantages for separating multiples. Multiple parts can be made on the bending machine and then separated by laser cutting. Up to 25% material can be saved.

Machining quality

Using laser technology prevents part deformation, improves processing quality and guarantees accuracy and repeatability. It is ideal for preparing parts for assembly by robots at a later stage. The benefit is even more obvious when processing thin walled tubes.

The advantages of the fiber laser

- in addition to mild steel, stainless steel and aluminium alloys, fiber laser can also cut copper and brass

- the higher cutting speeds offered by the fiber laser enhances the production capacity of the machine

- higher wall plug efficiency lowers power consumption and hence considerably reduces the installed power requirement

- maintenance free

…to explore new solutions in a simple manner

Process

LT-FREE HIGH FLEX version

Universal version for bent and hydroformed tubes, flat and preformed sheets or welded assemblies. Dual robots and dual table handling system with pallet which can be automatically separated from the scrap collection box.

High productivity version for preformed and hydroformed sheets with independent part loading and unloading during the cutting cycle. Single handling table system with automatic scrap conveyor.

LT-FREE PIECE VALUE version

LT-FREE ENTRY LEVEL version

Version for processing preformed, hydroformed and pre-assembled flat sheets without independent loading and unloading. Dual fixed table handling system with dedicated tools.

Applications