Best price to quality ratio - delivered

LT722D

Description

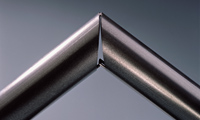

The LT722D laser tube cutting system provides 20% higher production rate than normally experienced in the field combined with a unique level of flexibility and automatic adjustments. This feature makes it suitable for both small batches or large runs. With capacities up to 152mm diameter and maximum lengths up to either 6500mm or 8500mm (on demand), the LT722D laser cutting system offers the following features :

- Fully CNC programmable adjustments

- Changeovers in less than 3 minutes

- Technological database for tubular components based on thousands of on filed applications

- Fast programming: from design to finished part in less than 10 minutes with unskilled operators

- Fully automatic bar handling from bundle including measuring, feeding, cutting and unloading Minimum bar waste.

- Standard Artube CAD-CAM software control packages specifically designed for single and assembled tube programming allow extremely high exploitation of the system.

Solutions

Available as part of the system :

- Weld seam detector

- Control device for enhanced piercing

- Unloading system lengths of 3500-4500-6500mm

- Separation and collection of different lengths

- Tube cleaning device to preserve tube I.D. integrity. This is particularly suitable for stainless steel tube used in the food industry, furniture, automotive exhausts and catalytic silencers.

Processes

More in particular, the combination of laser and bending processes in a production cell allows :

- High repeatability and quality thanks to the mask control on 100% of the products

- Simplified production process. Further piece machining on additional equipment is not required

- Guarantee of flexibility for further different uses of the system.

The process includes more machining in one cycle:

- Load

- Laser cutting

- Unload

- Precise piece orientation to guarantee the correct positioning after the bending

- Bending

- Unload

This process is particularly suitable for applications such as furniture, automotive and motorcycle.