Best price to quality ratio - delivered

LT8

Description

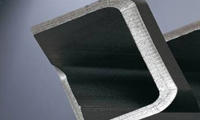

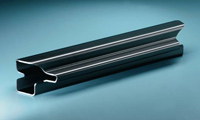

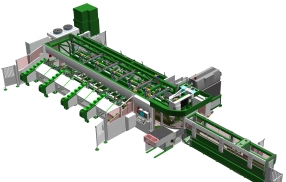

The LT8 is a 3D laser pipe cutting machine that excels for the highest flexibility and user-friendliness, as well as for top quality and extremely precise laser cutting, on tube diameters from 12 to 220 mm and a bar weight up to 35 Kg/m. Equipped with a tilting head, it allows 3D cutting on all sections (open and special profiles included). Due to an efficient automatic loading system combined to a unique and ingenious unload, the productivity of the LT8 has no comparisons in its range. The automatic nesting software combined with the reduced end bar scrap, helps still better to exploit the available material. Complex productions such as cutting different pieces on the same bar or batch changing among bars with different sections, are managed in automatic. The machine is able to propose and select the best suited choice for every production phase. Expert operators can anyway manually handle every setting. Available with an automatic bundle (capacity 5.000 Kg) or step loader and an automatic single bar loader, or with two automatic loaders. The second option doubles the already considerable quantity of material ready to be cut. The Artube environment, i.e. the exclusive Artube CAD-CAM, for the quick programming of complicated structures and the immediate exploitation of the machine potential, is available also on the LT8.

The LT8 is a 3D laser pipe cutting machine that excels for the highest flexibility and user-friendliness, as well as for top quality and extremely precise laser cutting, on tube diameters from 12 to 220 mm and a bar weight up to 35 Kg/m. Equipped with a tilting head, it allows 3D cutting on all sections (open and special profiles included). Due to an efficient automatic loading system combined to a unique and ingenious unload, the productivity of the LT8 has no comparisons in its range. The automatic nesting software combined with the reduced end bar scrap, helps still better to exploit the available material. Complex productions such as cutting different pieces on the same bar or batch changing among bars with different sections, are managed in automatic. The machine is able to propose and select the best suited choice for every production phase. Expert operators can anyway manually handle every setting. Available with an automatic bundle (capacity 5.000 Kg) or step loader and an automatic single bar loader, or with two automatic loaders. The second option doubles the already considerable quantity of material ready to be cut. The Artube environment, i.e. the exclusive Artube CAD-CAM, for the quick programming of complicated structures and the immediate exploitation of the machine potential, is available also on the LT8.

Active Tools : Super fast oxygen piercing with the Active Piercing and Active Focus functions

Solutions

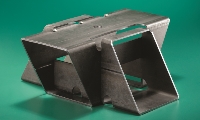

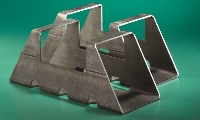

3D Cutting possibilities

The machine standard configuration is fitted with a tilting axis (± 45°) allowing geometry flaring operations to be carried out (bevel angle). Generally, 3D processes are used for large and thick tubes to be welded or for joints or couplings requiring an accuracy that could not be obtained otherwise

With a capacity of 5000 Kg, it can be installed on the front or the rear side of the machine, combined with all other loader types. Automatic single bar loader, already available in base configuration, equipped with an independent length measurement system.

Automatic bundle loader

Step loader

Designed to automatically load up to 6 single bars onto cradles, and to maintain orientation. This feature is particularly critical when there are special sections.

Tube cleaning device to preserve tube I.D. integrity. This is particularly suitable for stainless steel tube used in the food industry, furniture, automotive exhausts and catalytic silencers. Weld seam detector to identify the weld position and command an opportune rotation of the bar before starting the cut processing. The fully automatic supporting rollers between the spindle and the steady rest, follow the tube profile sustaining it during the rotations, without sliding and for this reason without scratching its surface.

Storage benches

Storage benches equipped with powered chains and wheels on the bottom, facilitate piece handling and allow access with pallet truck. Short piece unloader, for pieces up to 500 mm, conveys them automatically outside the machine into the collecting box

Tube cleaning device

Why A Lt8

....it adapts to the production

Thanks to the various loading devices and endless unloading positions that can be programmed, it is certainly a value to be able to:

- order the production of pieces per type at outlet.

- automatically implement production batches consisting of different sections.

- interrupt the production of one batch to insert the production of another unscheduled job and then restore production of the previous batch from where it left off.

....it grows over the years

The machine can be expanded at any time with the addition of a further bundle or pitch-pitch loader instead of the automatic single bar loader, t the position of the two loaders can be inverted to adapt to new production layouts; this means modular design for us.

....it simplifies the production process

Thanks to the cutting head with tilting axes (3D) bevels and semi-bevels can be performed to simplify the fitting/welding operations of medium/large thickness tubes.

....it satisfies even the most exacting applications

Precision in the machining operations and productivity must be backed by effective handling of the pieces. That's why a set of supports along the working axis is manufactured in such a way as not to cause any friction on the tube and follow the profile during rotation. Likewise, the unloading device is fitted with a gripper that picks-up each piece as soon as it has been completed and transfers it to the programmed unloading position, without collisions or falls due to gravity. In this way, the production is not slowed down and keeps its value

....it is ready to grasp new opportunities

The system has been designed to provide the utmost flexibility and be able to process special, open, concave and asymmetric sections without any particular difficulty. Each special section can be a business opportunity or the solution to an implementation problem that would otherwise be critical.

Applications