Best price to quality ratio - delivered

LT5

Description

LT5 is a Lasertube machine, designed to cut from small to medium diameters and thicknesses, easy to use. Ideal for all situations where you do not need to change frequently production and there are no special sections or open profiles to cut. LT5 is equipped with:

- unloading and support system of cut pieces in lengths: 4500 mm

- separating, collecting and palletising systems can be integrated after the unloader

- a device named "spoon" for maintaing cleanliness of the tube internal surface. This option is particularly useful on certain applications where stainless tube is involved (food industry, furnishings, exhaust pipes, catalytic pots).

- weld seam detection

- a 1 kW fiber laser source, particularly suited for processing the materials and thicknesses indicated in the following table:

| Materials | Thickness |

| Stainless Steel | 4 mm |

| Mild Steel | 6 mm |

| Aluminium | 3 mm |

| Brass | 3 mm |

| Copper | 2 mm |

LT5 has the same features and the same benefits of other Lasertube models with a lower investment level. It 's suitable to cut standard tubes up to 13.5 kg / m weight and in particular:

- Round tubes up to 120 mm diameter

- Square up to 100 mm

- Rectangles, ovals and elliptical semi-flat/full up to 120x70 mm

The main features are tube automatic manipulation, from bar loader to piece unloader, easy to use The programming software Artube is a three-dimensional, parametric, Artube CAD-CAM package specifically designed, developed and dedicated for tube applications, that amplifies the productivity potential of the machine

Solutions

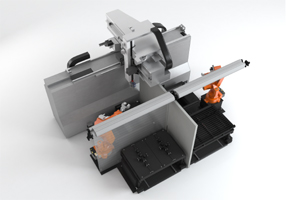

Dual robot station

The dual robot station configuration allows independent loading and unloading without interrupting the laser cutting process hence boosting productivity.

The large-capacity loader is designed to automatically handle bundles of tubes (round, oval) as well as packages of square and rectangular tubes; Length of each tube is measured during the preloading phase. This information is used by the machine to optimise the nesting and minimise the end scrap; The tube is supported and guided during each phase to ensure the maximum accuracy of cut parts and rotect the tube surface from scratches.

Efficient handling of tubes

Handling of parts to be machined

The part is not moved during the cutting operation. In this way, top-notch accuracy is guaranteed by a five-axis system and the flexibility of a robot handling system.

WHY LT5

The advantages of the fiber laser

- In addition to mild steel, stainless steel and aluminium alloys, fiber laser can also cut copper and brass;

- The higher cutting speeds offered by the fiber laser enhances the production capacity of the machine;

- Higher wall plug efficiency lowers power consumption and hence considerably reduces the installed power requirement;

- maintenance free.

- The integration of electric cabinets on one end of the machine allows access and passage on both sides along its entire length.

- Large doors with double opening at the front offer easy access for adjustments and maintenance.

- The operator console can be easily turned so as to have the complete visibility of the cutting process at all times.

- Optional chain conveyors can be installed on both sides of the machine to carry the cut pieces at a convenient height for easy collection.

…to explore new solutions in a simple manner

Applications